Deep down in southern Russia, close to the Kazakh border, the Ural Steel mill in Novotroitsk was founded in 1955 under the name Orsko-Khalilovsky Iron-and-Steel Works.

In the same year blast furnace no. 1 went into production.

The first steel was produced at open-hearth furnace no.1 in 1958.

In 1960 the 2800-mm plate rolling mill no.1 was installed.

A section rolling mill was put into operation in 1969.

In 1978 a 800-mm wide strip universal rolling mill was commissioned .

The EAF Shop was built in 1981.

1983 – The first continuous casting machine was put into operation at the EAF shop.

Today Ural Steel runs a coking plant,four blast furnaces, two electric arc furnaces (100 ton each) and four rolling mills.

Further images at Stahlseite.

Category Archives: Other

The Smallest Active Blast Furnace

I ever visited is located in the southern Ural, Russia.

The 250m³ (9000 cu-foot) furnace produces ferromanganese casted in pig beds.

The Satka Iron Smelting Works is the oldest existing iron producer in the Ural and among the first to be built in Russia.

Settled on the banks of the Bolshaya Satka river the mill went into production in 1758 founded by Baron Stroganov.

Two blast furnaces and 12 hammers were in operation.

In the 1860ies a puddling steel mill was added.

Since 1910 ferro alloys were produced.

In the 1930ies more than 1300 people worked in the mill, cast iron became the major product.

After financial troubles the plant became partly idled in the 1990ies until the Ivanov family coming from the Swerdlowsk region took over in 2001 annd decided to switch production to high carbon ferromanganese an alloying element for the steel industry.

Satka Iron Smelting Works today runs two blast furnaces of 250m³ and 350m³.

Further images at Stahlseite.

URAL

700 Ton Open Hearth Furnace

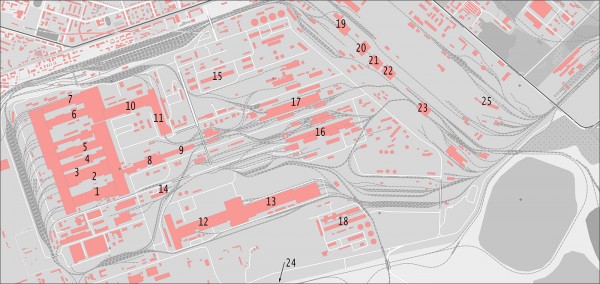

The steel mill in Kryvyi Rih (Russ. Krivoy Rog) was founded in 1931 on the rich iron or deposits of the Ukrainian Kryvbas basin.

In 1934 the mill was ready to produce hot metal out of one blast furnace. By 1939 three blast furnaces a coke plant and a Bessemer shop were in operation. In the second world war the Kryvyi Rih Metallurgical Works were dismantled by the Soviets and the remains destroyed by the German army.

In 1949 blast furnace No.1 was blown on. By 1960 four rolling mills and a 600 ton open hearth furnace were installed.

Blast furnace No.7 was built in 1962, No. 8 and No. 9 (one of the largest worldwide) followed in 1970 and 1974.

In 1996 the Kryvyi Rih State Mining and Metallurgical Combine (Krivorizhstal) brought together the metallurgical and the mining activities in the Kryvbas basin.

In 2004 the mill was privatized for the first time to an Ukrainian syndicate.

This was canceled one year later and the second privatisation found the Mittal Steel company as a new owner.

Since 2007 Krivorizhstal is part of the worlds largest steel company ArcelorMittal.

Today ArcelorMittal Kryvyi Rih employs 35000 people main products are billets, bars, rod and wire.

Further viewing.

1: Light-section mill 250-2

2: Rod mill 150-1

3: Light-section mill 250-1

4: Light-section mill 250-3

5: Light-section mill 250-4

6: Light-section mill 250-5

7: Rod mill 250-3

8: Blooming mill No.1

9: Soaking pits

10: Blooming mill No.2

11: Soaking Pits

12. Light-section mill 250-6

13: Wire mill

14: Forge shop

15: Oxygen plant

16: BOF shop (6×160 ton)

17: Open hearth shop (1×550 ton, 1×700 ton)

18: Power station

19: Blast furnace No.8

20: Blast furnace No.7

21: Blast furnace No.6

22: Blast furnace No.5

23: Blast furnace No.1

24: Blast furnace No.9

25: Coke plant (6 batteries)

Donetskstal, the last days of Siemens-Martin

The video shows the Donetskstal open hearth shop a few days before it was closed down for good in April 2012.

Donetskstal was founded in 1870 by the Welsh engineer John Hughes.

Donetskstal was founded in 1870 by the Welsh engineer John Hughes.

Most installations were imported from England and iron production in one blast furnace started in 1872.

By 1910 the plant had 6 blast furnaces, 9 open-hearth furnaces, 2 Bessemer converters, blooming, rail, structural, sheet, and some section rolling mills and a a coking plant.

From 1928 to 1961 the mill was named Stalino Iron Works.

In 1953 the 2300mm plate mill was installed which is still in use today.

Blast furnace 1 was built in 1956,NO 2 one year later. Both where completly modernised in 2002 and 2006.

One of the first continuous casters worlwide was built in 1960.

Two blast furnaces and several pig iron casters are actually producing.

More inside views.