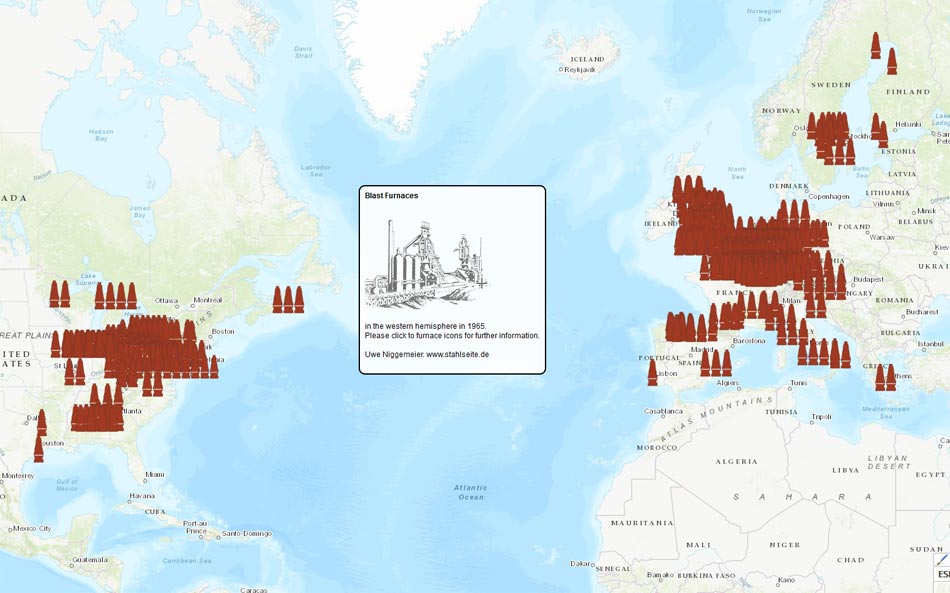

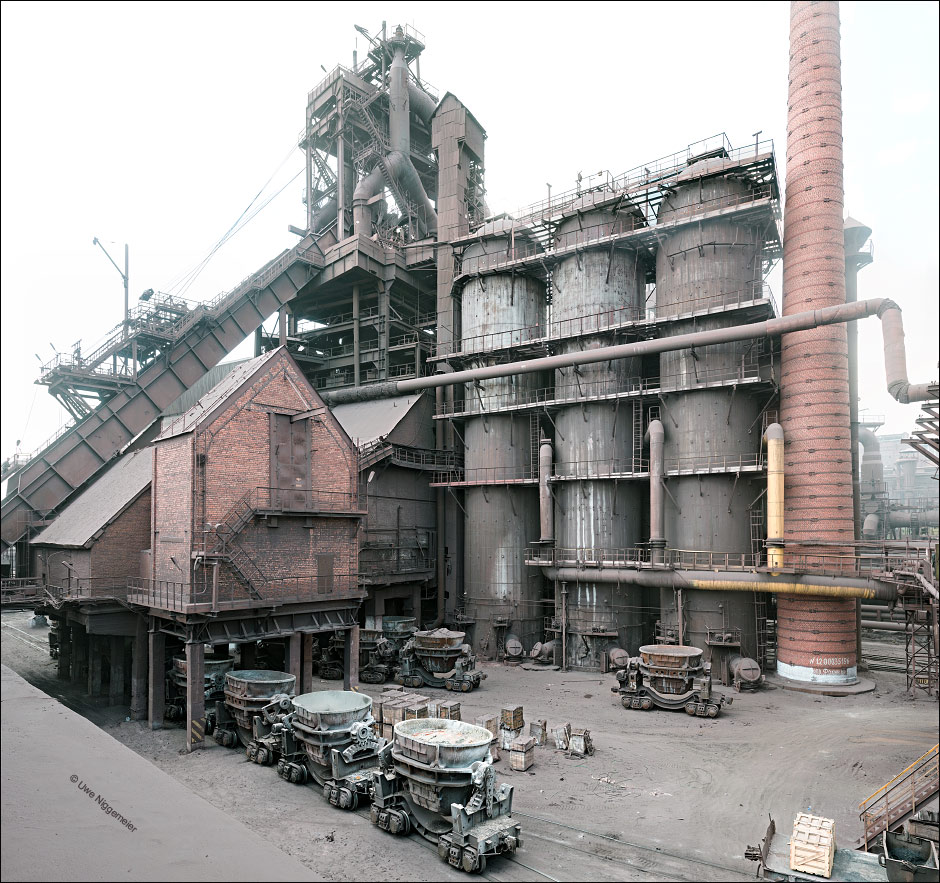

16, according to my estimation this is the largest number of blast furnaces in a steel plant that currently exists. And that probably applies to the past as well.

US Steel’s Gary works in it’s heydays never had more than 12, Sparrows Point 10. Reichswerke in Salzgitter, Germany had 32 planned but only 12 were completed.

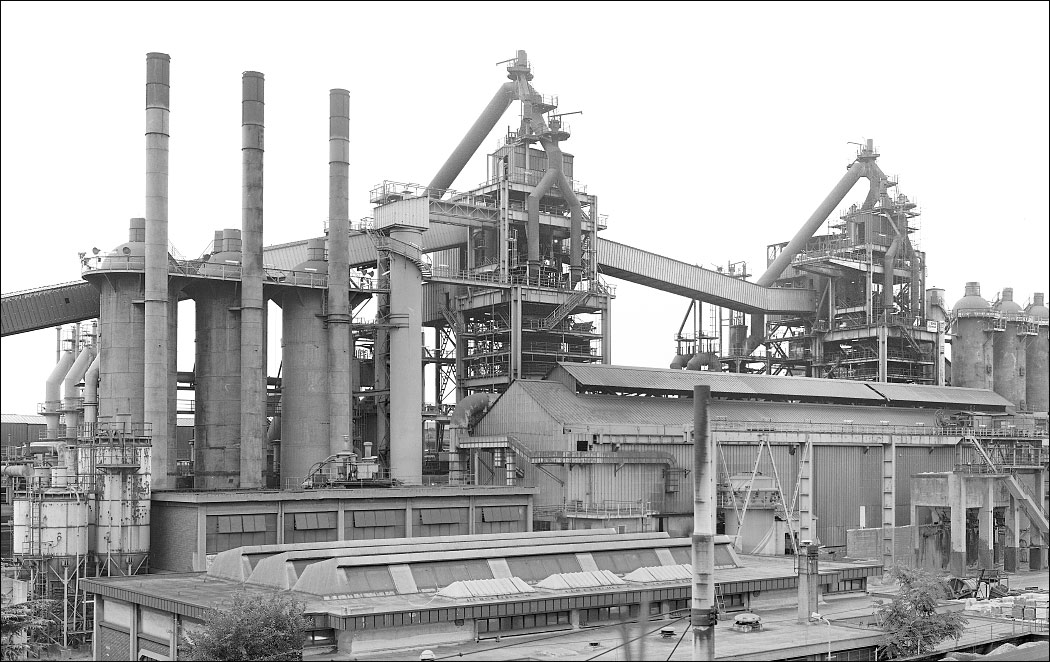

Rizhao Steel in China (Shandong Province) was founded in 2003. After only 181 days of construction, the first blast furnace was blown in September 2003. By 2008, 15 additional furnaces had been built (cap 7.5 mio t/y).

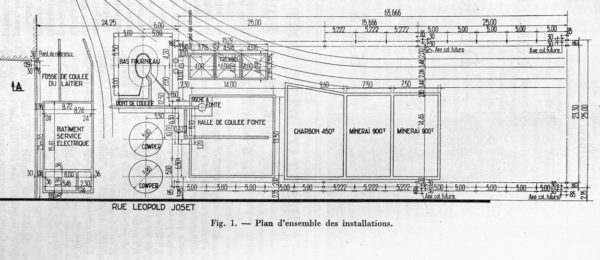

The small size of the blast furnaces (2 x 450 m³, 2 x 530 m³, 2 x 580 m³, 10 x 1080 m³) is striking. This would have made the plant uncompetitive in Western Europe and especially in North America already in the 1960s.

The installation of such small furnaces was widespread in China (presumably due to poor coke quality and a lack of know-how) until the economic crisis of 2008.

For economical and ecological reasons, however, the days of such blast furnaces are probably numbered in China as well.

Rizhao steel is building three new blast furnaces right now 3000 m³ volume each.