In 1965 there were 237 blast furnaces at 72 locations in the U.S. . This series will briefly introduce all of them.

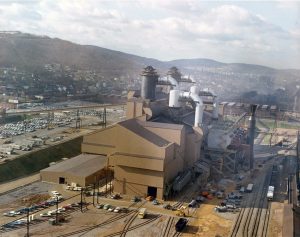

In 1965, the United States Steel Corp. was the largest steel producer in the world. In the U.S. it still operated 16 blast furnace sites. One of their lesser known plants was Central Furnaces in Cleveland, OH.

This plant was founded in 1881 by the Cleveland Rolling Mill Co. and supplied iron to the Newburgh steel mill until it was closed in 1933.

After that, the Cuyahoga River plant became a pure ironworks, selling merchant pig iron and hot metal to foundries.

In the 1960ies, after the demolition of furnaces B & C and the rebuilding of blast furnace A in 1954 the mill operated two furnaces.

Blast furnace A now mostly supplied pig iron to the Ford Motor Company’s Cleveland

engine plant.

With no integrated steel production the Central Furnaces became what USS called a “marginal unit” and were shut down in 1978.

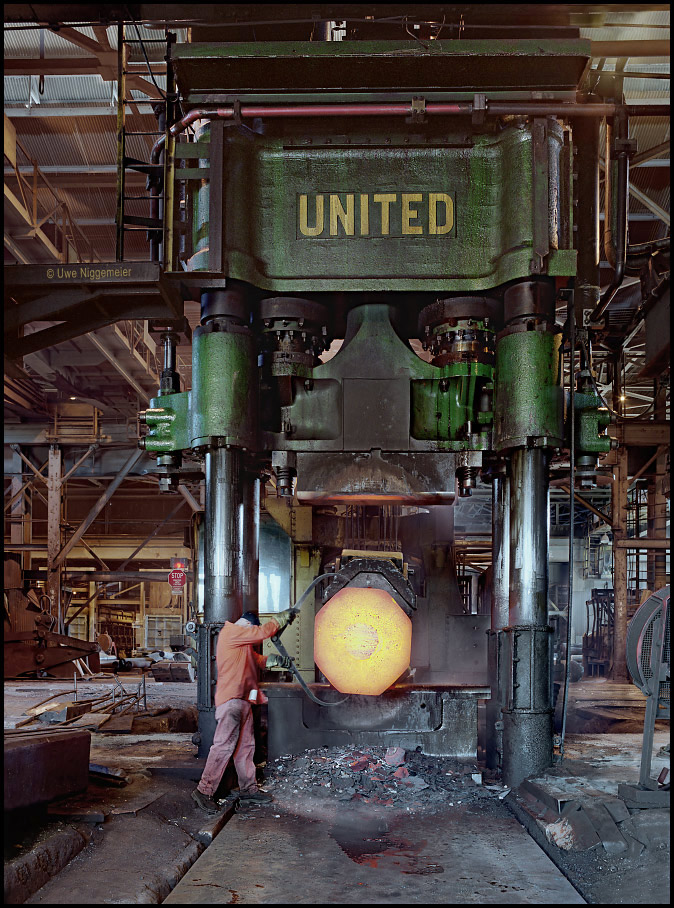

Famous German industrial photographers Bernd and Hilla Becher visited the plant in 1979, pictures 3, 92 and 159 in their book “Hochöfen” (Blast Furnaces) show the furnaces.

- BF A: Ø 26’0” (7,92 m)

- BF D: Ø 22’6” (6,85 m)