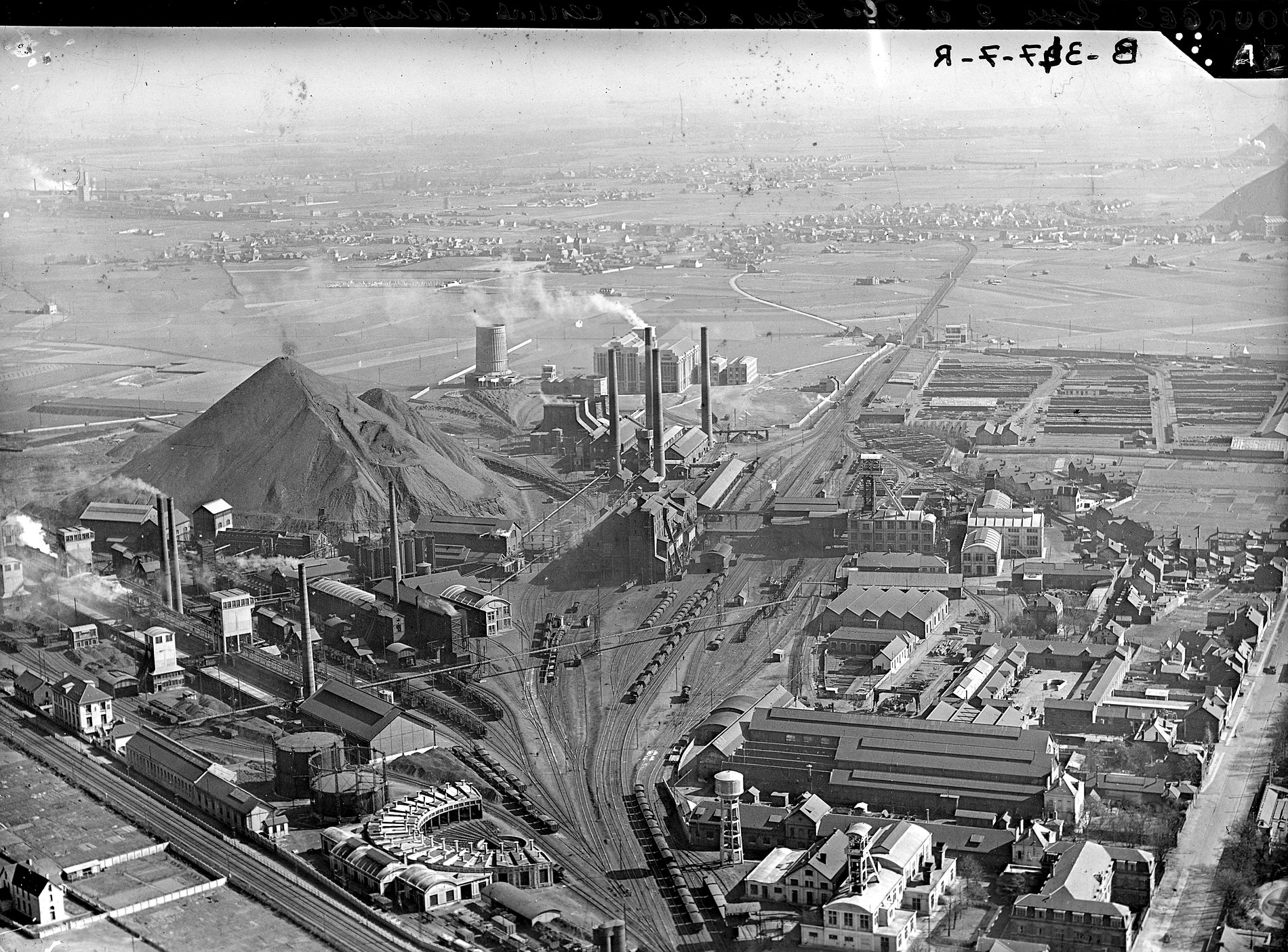

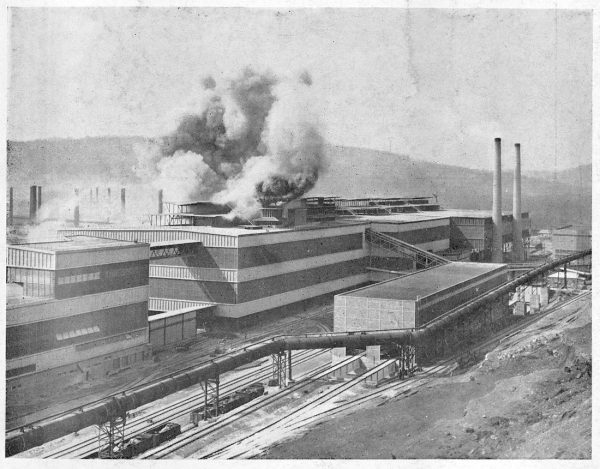

Shafts 2 and 2bis of the Sainte-Henriette colliery in Hénin-Beaumont with coking plant and power station in 1954.

The coking plant was shut down in 1958 and the mine was closed in 1970.

In the background on the left is the notorious Peñarroya lead and zinc smelter.

Category Archives: France

La belle France I.

Hütte im Sand

Vor 110 Jahren baute Frankreich sein erstes nasses Hüttenwerk an die Küste Flanderns.

Die Geschichte der Usine de Dunes ist heute weitgehend vergessen, obwohl es am Standort in Leffrinckoucke alles gab was ein integriertes Hüttenwerk ausmacht: Kokerei, Hochofen, Stahlwerke und Walzwerke.

1911 durch die aus dem Industrierevier von Saint-Étienne stammende Aciéries et forges de Firminy erbaut sollte das Werk in den Dünen Kokskohlen aus den nahe gelegenen Revieren Nordfrankreichs und Belgiens mit importiertem Hämatiteisenerz aus Schweden kombinieren.

Ein eigenes Hafenbecken am Canal de Furnes verband die Hütte mit dem Hafen von Dünkirchen.

Hochofen und Kokerei wurden während der Weltwirtschaftskrise Anfang der 1930er Jahre stillgelegt (die Kokerei erst 1977 abgerissen). Das SM-Stahlwerk, die Walzstrassen, Schmieden und die Radsatzfertigung blieben erhalten.

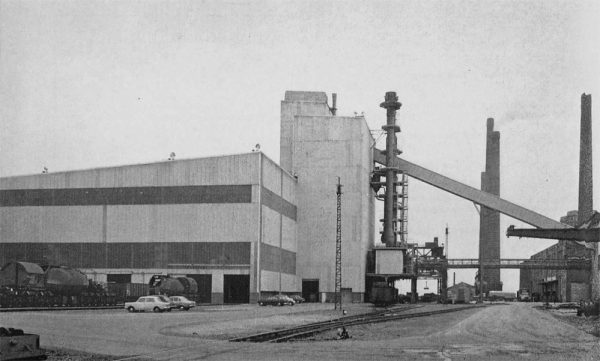

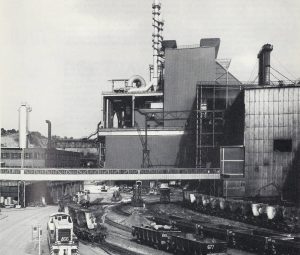

1969 beschloss der neue Inhaber (Creusot-Loire) das Werk durch den Bau eines LD-Stahlwerks an die neu gebaute Hütte von Usinor im 16 Kilometer entfernten Dünkirchen anzubinden, ein Liefervertrag für Roheisen an das SM-Stahlwerk bestand bereits. Nach nur 11 Monaten Bauzeit wurde der neue 60 t Konverter am 11. März 1971 erstmals abgestochen.

Die Hütte in Leffrinckoucke betrieb nun drei 100 t SM-Öfen ( 270.000 t/j), einen Elektrolichtbogenofen ( 80.000 t/j) und den neuen LD-Tiegel mit einer Jahreskapazität von 350.000 t.

Auf der Walzwerksseite waren eine Blockstrasse und zwei Stabwalzwerke in Betrieb.

Auch die Radsatzfertigung mit einer 6000 t Räderpresse war noch vorhanden. Die Versorgung mit Roheisen aus Dünkirchen erfolgte durch jeweils zwei 100/150 t Roheisenpfannen. Mehr als 3100 Beschäftigte arbeiteten nun am Standort.

Am 26. März 1978 ersetzte ein neuer 80 t Lectromelt UHP Lichtbogenofen die alten SM-Öfen. Wann das LD-Stahlwerk stillgelegt wurde ist mir leider nicht bekannt, vermutlich aber bei der Übernahme durch Usinor-Sacilor.

Seit den 1980er Jahren kam es dann zu zahlreichen Besitzerwechseln (Ascometall, Lucchini, Severstal, Swiss Steel).

Im Herbst 2017 wurde das Elektrostahlwerk und im April 2020 das letzte Walzwerk in Leffrinckoucke stillgelegt. Auch die verbliebene Wärmebehandlung mit 69 Beschäftigten soll verlagert werden.

Florange

Der Osten Frankreichs war einmal das Land der Blasststahlwerke, nirgends auf der Welt arbeiteten so viele Konverter wie auf der roten Erde Lothringens. 1965 waren es noch 81, sechs mehr als in der BRD.

Im Oktober 2011 legte ArcelorMittal in Florange die beiden letzten still.

2018 wurde das (längst feststehende) endgültige Ende der Flüssigphase im Tal der Fensch verkündet. Das Stahlwerk wartet seit dem auf seinen Abriss.

Der Komplex (inzwischen auch von der “Urbex”-Szene entdeckt) ist immer noch hochinteressant, birgt er doch Spuren von fünf verschiedenen Stahlwerken die die technische Entwicklung der Stahlerzeugung seit dem 2. Weltkrieg dokumentieren.

1948 war als Gemeinschaftsunternehmen verschiedener französischer Stahlhersteller die Société Lorraine de Laminage Continu (Sollac) gegründet worden. Ziel war es die immensen Investitionen für eine kontinuierliche Warmbreitbandstrasse nach amerikanischem Vorbild gemeinsam zu stemmen.

1954 ging das Walzwerk in Serémange im Fenschtal in Betrieb.

Um die neue Straße mit Vormaterial zu versorgen war geplant von der DEMAG, Duisburg im benachbarten Florange eines der größten Stahlwerke Europas bauen zu lassen.

Das kombinierte SM-Thomasstahlwerk sollte sechs Konverter und sechs Siemens-Martin-Öfen in Reihe umfassen. Gebaut wurden schließlich 4 Öfen und 4 Konverter in zwei Gruppen sowie drei Roheisenmischer. Das SM-Stahlwerk ging 1953 in Betrieb das Blasstahlwerk folgte zwei Jahre später.

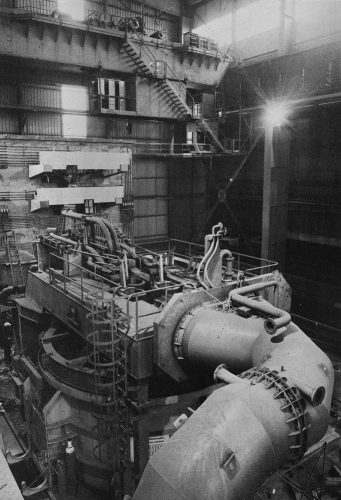

Da die Qualität des Thomasstahls für die Produktion von Feinblechen nur bedingt zu verwenden, der SM-Stahl verhältnismäßig teuer und das neue LD-Verfahren für die phosphorreichen lothringischen Erze ungeeignet war installierte Sollac anstatt eines fünften SM-Ofens ein Kaldostahlwerk.

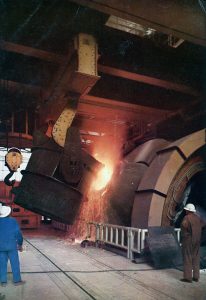

Der dort um seine Längsachse rotierende 110 t Sauerstoffaufblaskonverter wurde 1960 wieder von der DEMAG geliefert.

Im Oktober 1973 baute man zu Erprobungszwecken den Thomas-Konverter 4 zu einem 65 t L.W.S.-Konverter um. Bei diesem in Frankreich entwickelten Verfahren (Loire-Wendel-Sprunk) wurden Sauerstoff und Kalk von unten durch die Schmelze geblasen, so ließen sich in ehem. Thomaskonvertern hochwertige Stähle auch aus der lothringischen Minette erzeugen. Nach einer erfolgreichen Testphase rüstete man dann Ende 1975 auch die übrigen Thomas-Konverter um.

Ab 1976 begann dann die Planung eines zweiten L.W.S.-Stahlwerks mit 240 t Konvertern.

Dafür wurde noch im gleichen Jahr das alte SM-Stahlwerk stillgelegt und auf ein einem Teil seiner Fläche mit dem Bau der neuen Konverterhalle begonnen. Im Juli 1978 gingen die beiden L.W.S.-Konverter in Betrieb, ein zunächst geplanter dritter wurde nie gebaut.

Das kostenintensive Kaldostahlwerk legte die Sollac im Dezember 1978 still und auch das

L.W.S.-Stahlwerk 1 mit seinen vier 65 t Konvertern wurde im Sommer 1980 ein Opfer der Stahlkrise.

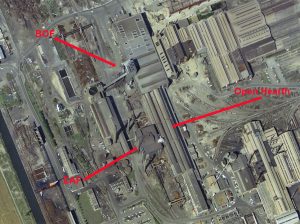

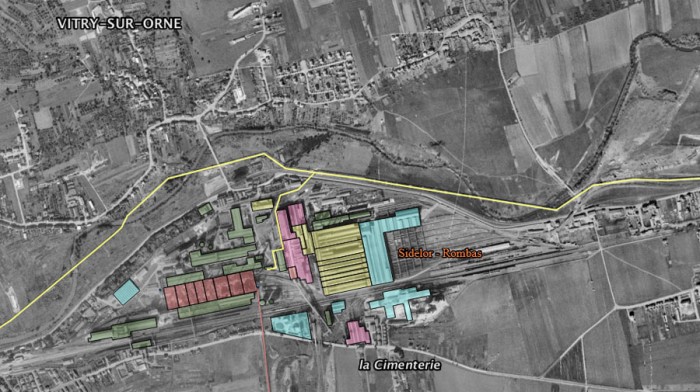

Von allen Stahlwerken und der Mischerhalle dürften heute noch Baulichkeiten erhalten sein, das L.W.S.-Stahlwerk 1 wurde etwa zur Hälfte (Konverter 3-4) abgerissen. Siehe Karte.

The last new blast furnace site in Lorraine

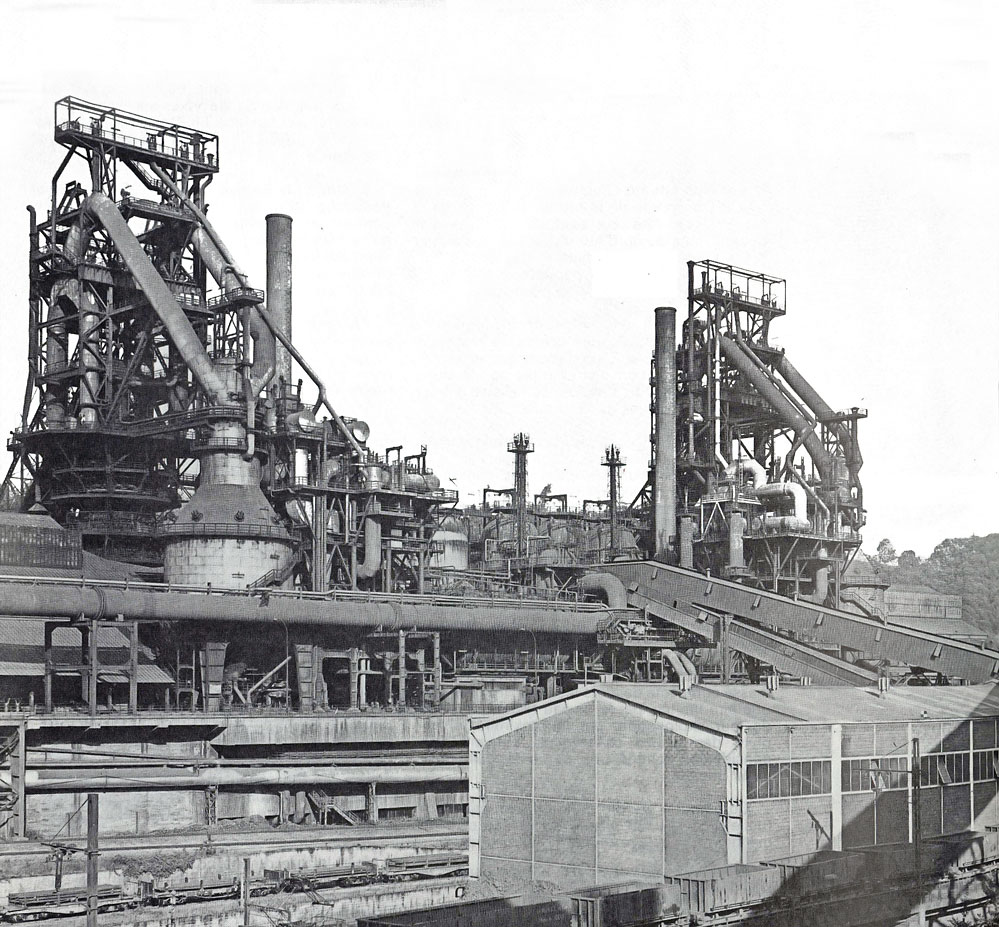

was built 60 years ago by Oberhausen-based GHH for the French steel group De Wendel in Jœuf.

The largest blast furnace in France at the time, J1, with a hearth diameter of 8.6 meters, was first blown in July 1961.

The slightly larger J2 furnace was commissioned three years later. The projected blast furnaces 3 and 4 were never realized.

A sintering plant was built in a side valley of the Orne with what was reportedly the largest sinter belt in the world at the time (288 m²).

In 1968, De Wendel merged with Sidelor and the blast furnaces and the Bessemer steelworks in the neighboring old Jœuf plant were shut down.

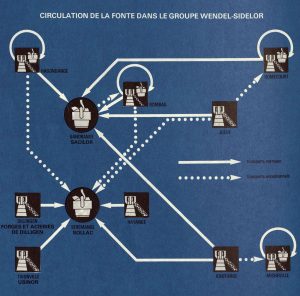

Blast furnaces J1 and J2 now became part of Wendel-Sidelor’s extensive pig iron supply. This included 22 blast furnaces (plus 8 in reserve) at 7 locations  with a daily capacity of 22,300 t.

with a daily capacity of 22,300 t.

The switch in iron ore supply to the French blast furnaces from low-grade domestic minette to high-grade imported ores in the 1970s and 80s brought an end to iron production at this remote site.

Furnace J1 was blown out on December 23, 1988, and blast furnace J2 on November 10, 1989.

Vallourec closes down tube mill in Deville.

Archives du ciel.

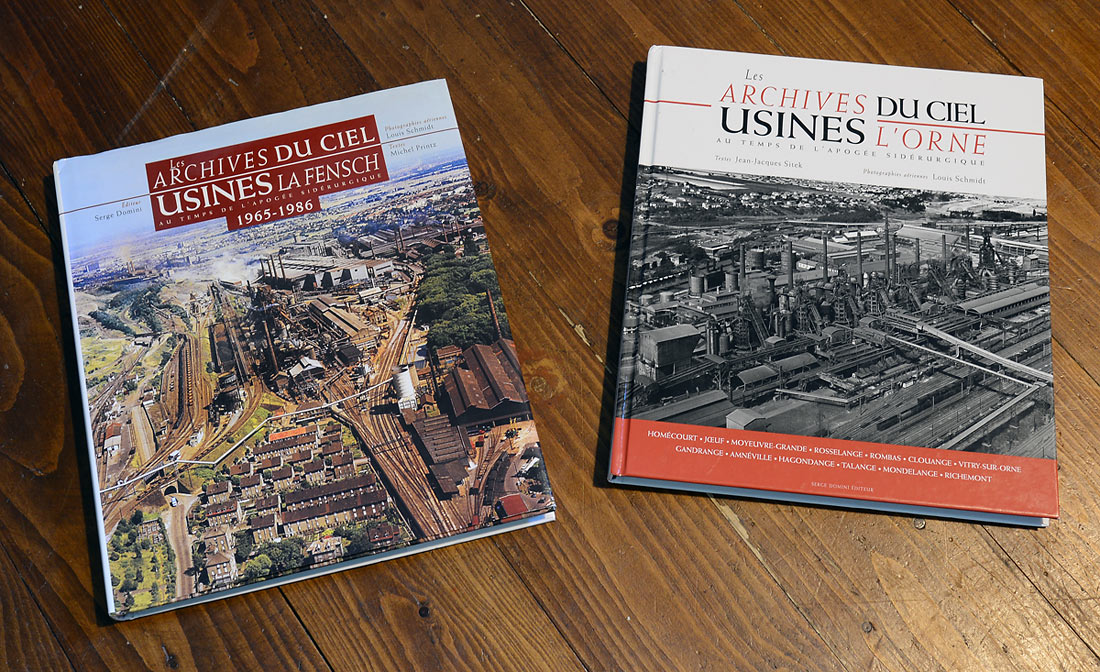

Die Archive des Himmels gehören zu den wenigen besitzenswerten Publikationen der letzten Dekade zur Geschichte der Stahlindustrie.

Beide Bände sind allerdings inzwischen schwerlich aufzutreiben umso größer daher die Freude nun auch den ersten Band mit den Luftbildern aus dem Ornetal bekommen zu haben.

Louis Schmidt hat in den 60er/70er Jahren genau wie die Bechers Industrie auf großformatigen Negativen abgelichtet. Allerdings von oben.

1983 ist Schmidt bei einem seiner Einsätze ums Leben gekommen.

Sehr schade, die Welt ist ohne solche Fanatiker eindeutig ärmer.

Aus der Zeit bis 1975 sollen 25000 Negative existieren, auch aus dem Ausland…

Longwy würde mir aber schon reichen.

Forging Big Stuff.

Rivers Of Steel: The Orne

Book About Longwy’s Legendary Steel Industry

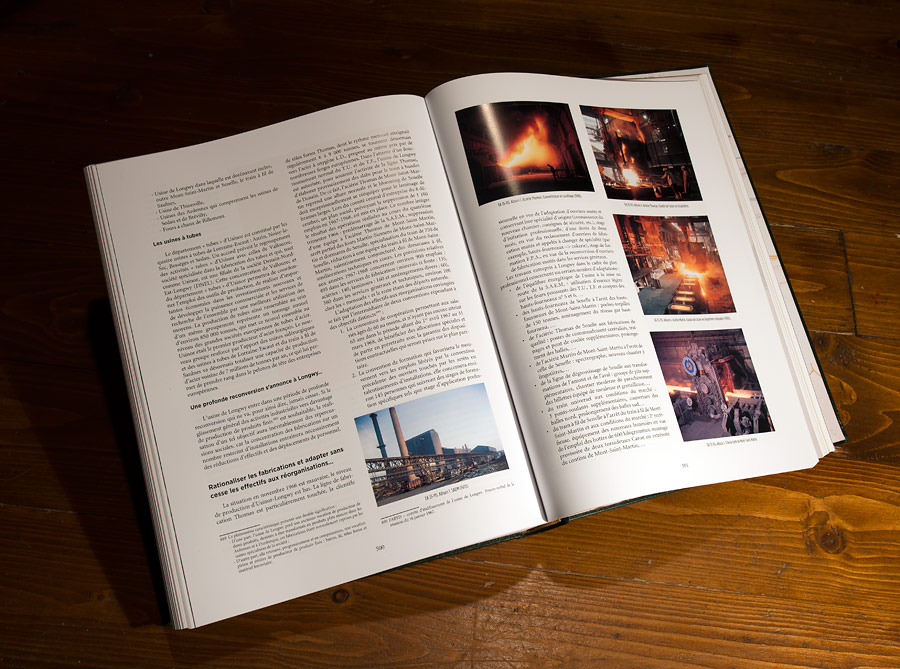

Already about a year old but still highly recommended:

“L’industrie du fer dans le bassin de Longwy des origines à nos jours”

588 pages crammed with information (in French) and hundreds of photos about Longwy’s legendary steel mills (Longwy, Senelle, La Chiers and Rehon).

60,00 EUR. ISBN/GTIN978-2-916782-62-1, Edition Fensch Vallee.