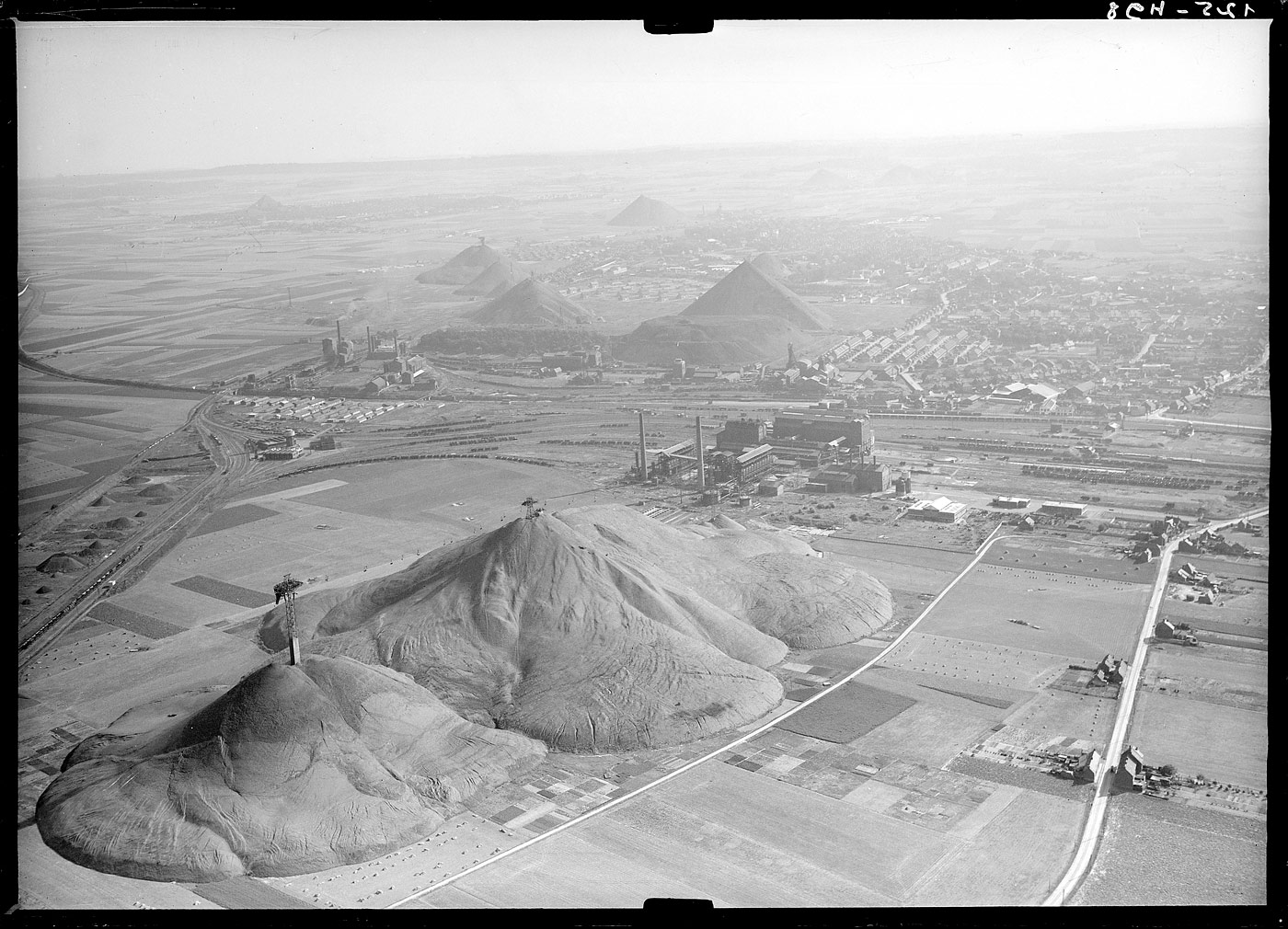

Mining landscape near Nœux-les-Mines, 8/1949.

Category Archives: Works

La belle France IV.

La belle France III.

La belle France II.

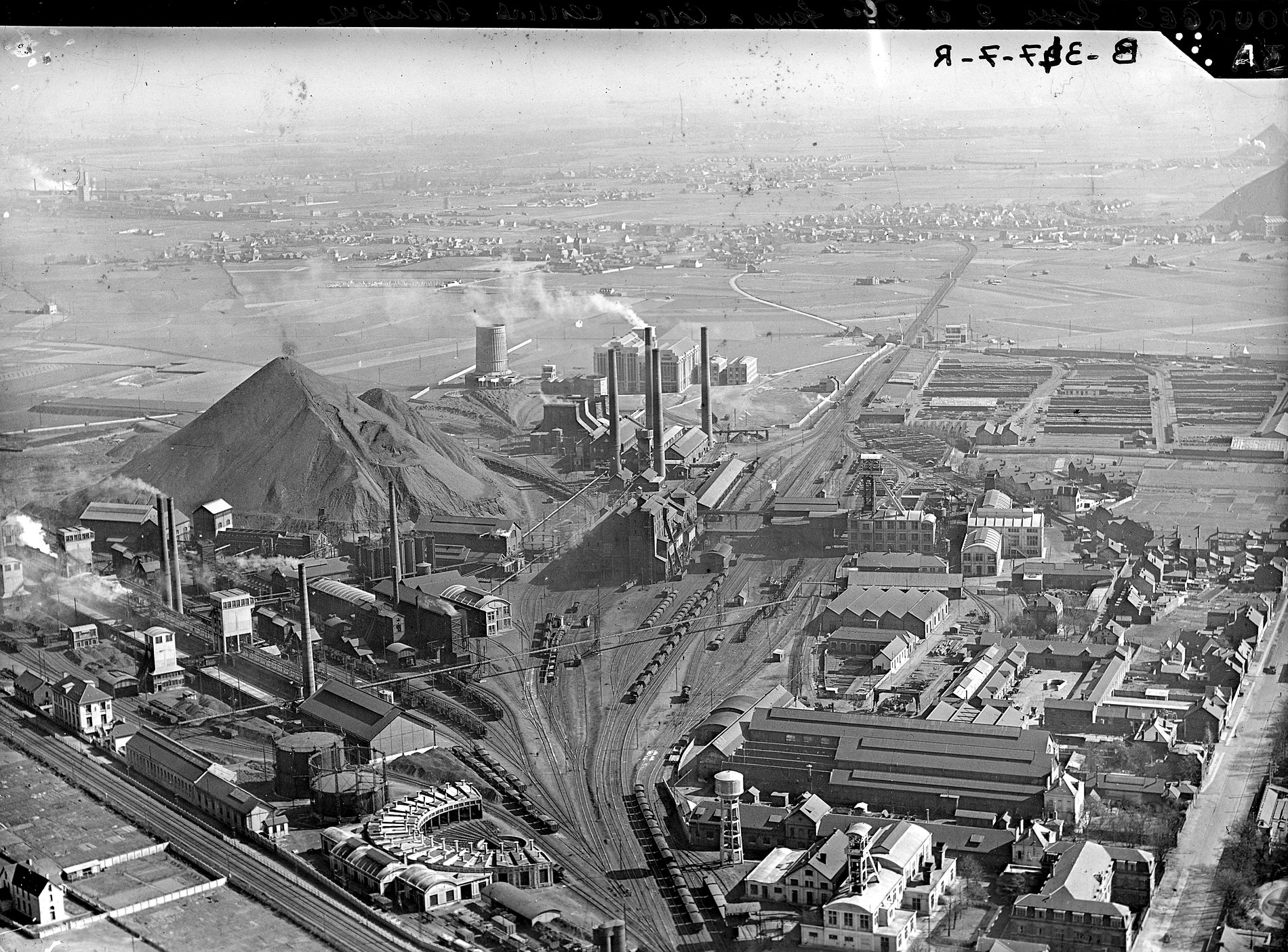

Shafts 2 and 2bis of the Sainte-Henriette colliery in Hénin-Beaumont with coking plant and power station in 1954.

The coking plant was shut down in 1958 and the mine was closed in 1970.

In the background on the left is the notorious Peñarroya lead and zinc smelter.

Beitz-Villa abgerissen.

© RVR, 2020, dl-de/by-2-0

Bei einer freitäglichen Coronawanderung habe ich gesehen, daß die 1953 von der Fried. Krupp AG für ihren Generalbevollmächtigten Berthold Beitz erbaute Villa in Essen-Bredeney Geschichte ist.

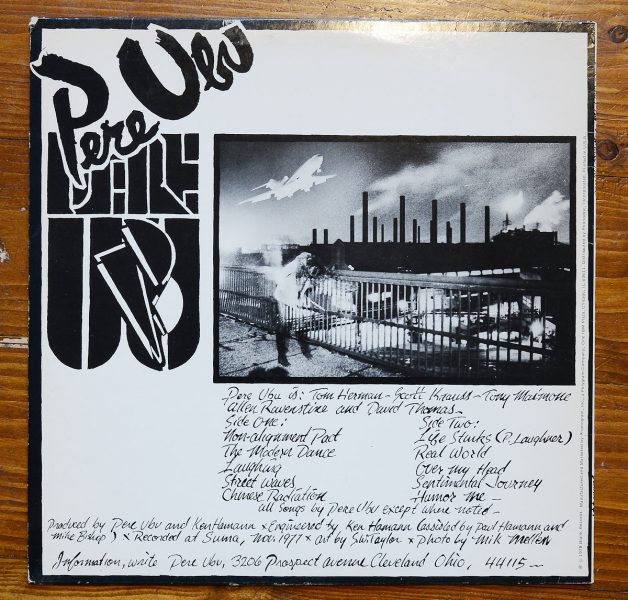

Where two passions meet.

The legendary US underground band Pere Ubu from Cleveland, Ohio was one of the first to address the atmosphere of their declining heavy industrial homeland in lyrics and on record covers.

From now demolished Pershing Av. bridge.

No. 1 slabbing mill in the foreground, no. 2 BOF right, open hearth shop in the background.

Frontman and mastermind David Thomas on growing up in Cleveland in the 1970ies:

We were savages living in the ruins of a great civilization of Rockefellers and Carnegies. Growing up, we owned downtown. Nobody wanted it. We roamed the streets like they were ours. The Flats was a place of deep mystery. It was our modern art museum. We would drive through the steel mills and within 20 yards of open blast furnaces. We weren’t duplicating those sounds. Those sounds were showing us the way to change the narrative vehicle of modern music.

(Cleveland Magazine, 11/22/2017)

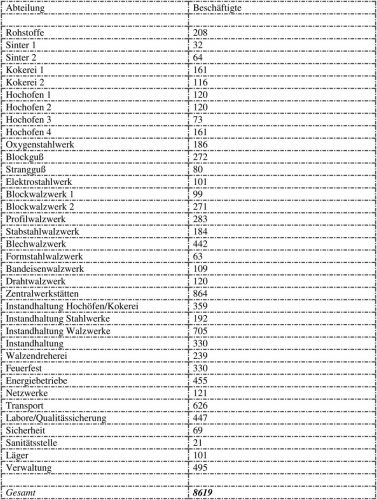

8619 Beschäftigte

hatte dieses mittelgroße Hüttenwerk mit einer Roheisenkapazität von 2,8 Mio. T/J in den 1970er Jahren (ohne Hauptverwaltung).

In den Medien werden bei der Berichterstattung über die Stahlindustrie meist Mitarbeiter aus dem Hochofen- oder Stahlwerksbereich gezeigt. Diese machten aber nur etwa ein Achtel der Gesamtbelegschaft eines Hüttenwerkes aus.

Dieses Dokument zeigt einmal wie sich die Beschäftigten auf die zahlreichen Abteilungen verteilten.

Die Friedrich Wilhelms-Hütte

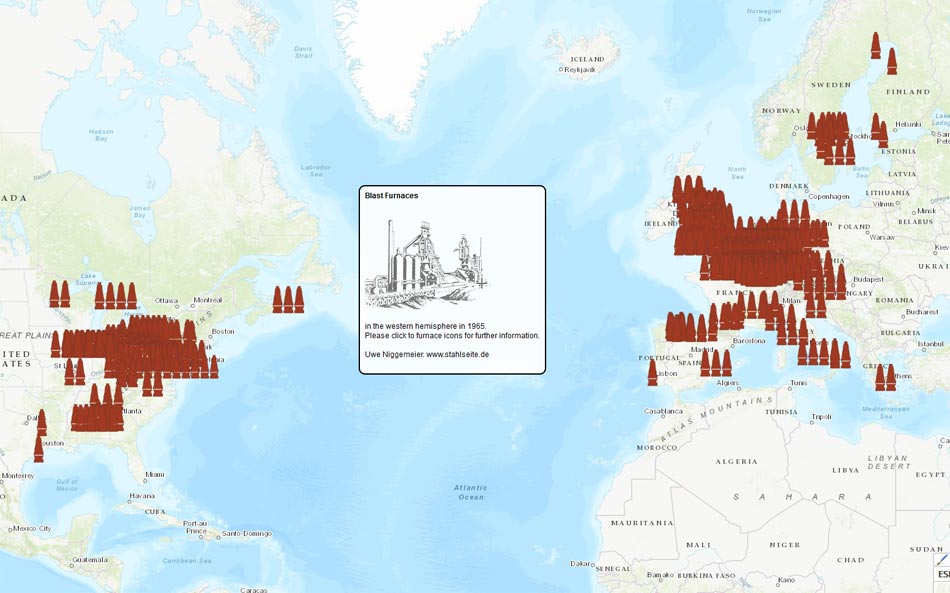

800 blast furnaces.

The blast furnace, as one hears from its operators, will soon follow the dinosaurs and disappear.

Therefore, as a by-product of the pandemic time-out, a contribution to its history:

The nearly 800 blast furnaces existing in the western hemisphere (so called “free world”) in 1965.

Corrections are welcome.

But please note that this map refers to the year 1965.

The big exit.

ArcelorMittal leaves the U.S. and makes former mining company Cleveland-Cliffs the largest hot strip producer in America.