Probably only very few industrial facilities still operate today that were financed by the Marshall Plan (European Recovery Program) between 1948 and 1952.

One of them is the 80” hot strip mill in Port Talbot, Wales.

It was to become the core unit of the expansion plan “K” for the steelworks of the Steel Company Of Wales on the Welsh coast.

From 1947 on, the Abbey Works were built on 220 hectares south of the existing Margam Works.

The largest single investment in the history of the British steel industry.

The fully continuous hot strip mill had 4 roughing stands and 6 finishing stands. It had a total driving power of 33500 kW. The plant was designed and built by United Engineering Comp. from Pittsburgh and financed with $27 million from the Marshall fund.

The fully continuous hot strip mill had 4 roughing stands and 6 finishing stands. It had a total driving power of 33500 kW. The plant was designed and built by United Engineering Comp. from Pittsburgh and financed with $27 million from the Marshall fund.

It went into operation in 1951 and is still largely unchanged today, except for the roughing stands (new construction in 2014).

Tag Archives: Hot Strip Mill

Voorwals

TKS legt Giesswalzanlage still.

Anläßlich ihres 20-jährigen Jubiläums wurde die GWA noch als weitsichtige und lohnende Investition bezeichnet, nun aber, nur ein Jahr später, wird sie stillgelegt.

Anläßlich ihres 20-jährigen Jubiläums wurde die GWA noch als weitsichtige und lohnende Investition bezeichnet, nun aber, nur ein Jahr später, wird sie stillgelegt.

Als die GWA im April 1999 in Betrieb genommen wurde war sie die erste Anlage ihrer Art in einem integrierten Hüttenwerk weltweit.

Offenbar hat sich die Erzeugung von Breitband in einer Hitze in diesem Rahmen aber nicht bewährt denn Thyssen-Krupp Steel kündigt an die Anlage zu einer Warmbreitbandstrasse klassischer Bauart umzubauen.

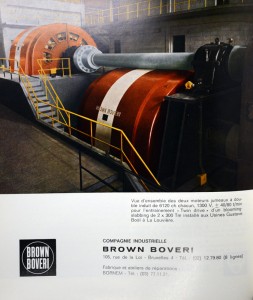

Back at La Louviere

Back at the old Gustave Boël site in La Louviere, Belgium after 13 years.

A lot has changed, no more steel making, no more continuous casting, no more wire rolling.

NLMK from Russia took over in 2011 and still operates the 72″ hot strip mill which was put into operation in November 1965.

Together with the LD steelworks, it was part of a major investment in anticipation of the extension of the Brüssel-Charleroi Canal for 1350 t vessels.

The roughing stand was supplied by Maschinenfabrik Sack in Düsseldorf – the finishing line was a cooperation between Siemag from Hilchenbach and the United Engineering and Foundry Company from Pittsburgh.

The roughing stand was equipped with two 5000 kW DC engines and each finishing stand was driven by a 4500 kW DC motor.

Further images on my website.

Salzgitter Hot Strip Mill

In 1963 the wide hot strip rolling mill in Salzgitter was the third of it’s kind to be installed after the war in Germany.

Images here.