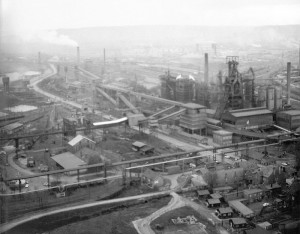

Vor 110 Jahren baute Frankreich sein erstes nasses Hüttenwerk an die Küste Flanderns.

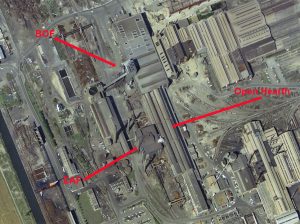

Die Geschichte der Usine de Dunes ist heute weitgehend vergessen, obwohl es am Standort in Leffrinckoucke alles gab was ein integriertes Hüttenwerk ausmacht: Kokerei, Hochofen, Stahlwerke und Walzwerke.

1911 durch die aus dem Industrierevier von Saint-Étienne stammende Aciéries et forges de Firminy erbaut sollte das Werk in den Dünen Kokskohlen aus den nahe gelegenen Revieren Nordfrankreichs und Belgiens mit importiertem Hämatiteisenerz aus Schweden kombinieren.

Ein eigenes Hafenbecken am Canal de Furnes verband die Hütte mit dem Hafen von Dünkirchen.

Hochofen und Kokerei wurden während der Weltwirtschaftskrise Anfang der 1930er Jahre stillgelegt (die Kokerei erst 1977 abgerissen). Das SM-Stahlwerk, die Walzstrassen, Schmieden und die Radsatzfertigung blieben erhalten.

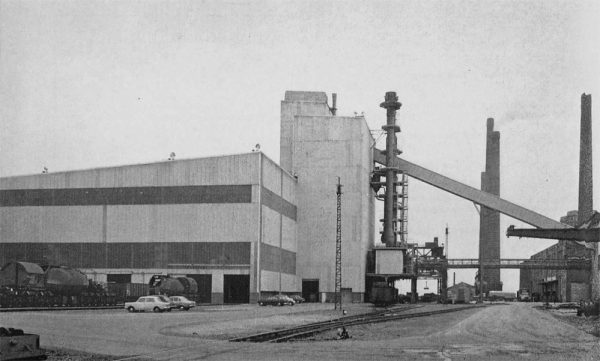

1969 beschloss der neue Inhaber (Creusot-Loire) das Werk durch den Bau eines LD-Stahlwerks an die neu gebaute Hütte von Usinor im 16 Kilometer entfernten Dünkirchen anzubinden, ein Liefervertrag für Roheisen an das SM-Stahlwerk bestand bereits. Nach nur 11 Monaten Bauzeit wurde der neue 60 t Konverter am 11. März 1971 erstmals abgestochen.

Die Hütte in Leffrinckoucke betrieb nun drei 100 t SM-Öfen ( 270.000 t/j), einen Elektrolichtbogenofen ( 80.000 t/j) und den neuen LD-Tiegel mit einer Jahreskapazität von 350.000 t.

Auf der Walzwerksseite waren eine Blockstrasse und zwei Stabwalzwerke in Betrieb.

Auch die Radsatzfertigung mit einer 6000 t Räderpresse war noch vorhanden. Die Versorgung mit Roheisen aus Dünkirchen erfolgte durch jeweils zwei 100/150 t Roheisenpfannen. Mehr als 3100 Beschäftigte arbeiteten nun am Standort.

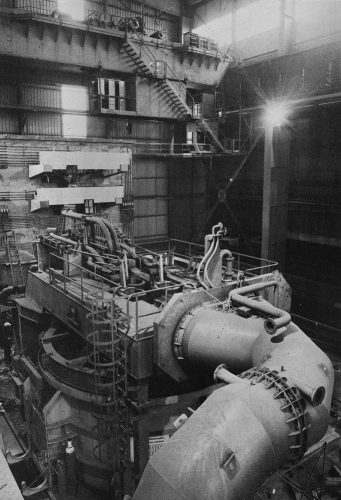

Am 26. März 1978 ersetzte ein neuer 80 t Lectromelt UHP Lichtbogenofen die alten SM-Öfen. Wann das LD-Stahlwerk stillgelegt wurde ist mir leider nicht bekannt, vermutlich aber bei der Übernahme durch Usinor-Sacilor.

Seit den 1980er Jahren kam es dann zu zahlreichen Besitzerwechseln (Ascometall, Lucchini, Severstal, Swiss Steel).

Im Herbst 2017 wurde das Elektrostahlwerk und im April 2020 das letzte Walzwerk in Leffrinckoucke stillgelegt. Auch die verbliebene Wärmebehandlung mit 69 Beschäftigten soll verlagert werden.