After nearly 120 years of steel production the former Carlshütte in Thionville, France was closed down last week.

Further images.

Category Archives: France

Real Heavy Plate

up to 900mm thick and 80 tons heavy is still produced at the old Marrel Frères site in Chateauneuf, France.

The steel mill was founded in 1867 by the Marrel brothers.

Main product were flat irons and armoured plates.

In 1932 a unique combined heavy plate rolling and forging mill was installed that is still in use today.

In 1974 Marrel Frères became part of the Creusot Loire group and eight years later the production of long rolled products was transfered to St. Etienne and after the bancruptcy of Creusot Loire the mill became part of USINOR.

In the following years the company changed it’s name frequently (Creusot Loire Industrie, CLI Fafer, Usinor Industeel). Today the site is part of Industeel producing the largest heavy plate in Europe.

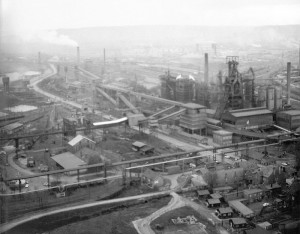

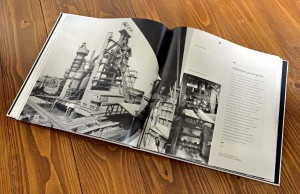

L’Usine De Thionville

Though much of Lorraine’s steel industry has vanished the old Carlshütte in Thionville is still around. At least parts of it. Like the electric arc furnace in the old open hearth shop now owned by Akers from Sweden.

Further viewing at stahlseite.

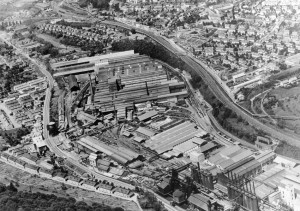

The mill in Thionville (German: Diedenhofen) on the banks of the river Moselle was founded by Carl Röchling from Völklingen, Germany and named “Carlshütte” in 1898. Lorraine was part of Germany from 1871 to 1918. Two blast furnaces were built and two more plus a Bessemer steel mill were added in 1906.

After the first world war the mill became French and was now called “Société Lorraine Minière et Métallurgique”.

A coking plant came into operation in 1928.

The “Aciéries de Longwy” took over the plant in 1933.

A forge, an open hearth melt shop and a foundry were added.

1953 saw a new owner: “Société Lorraine – Escaut“.

In 1964 blast furnace number 1 was replaced by a new furnace the largest in Lorraine capable of producing 2000 tons of pig iron a day. Furnaces No. 2,3 and 4 were closed down in between 1966 and 1970 and were all dismantled by 1972.

USINOR a large steel company from northern France took over the Thionville mill in 1966.

A new UHP 70 ton electric arc furnace replaced the old open hearth furnaces in 1973.

Plans to built a OBM oxygen steel making shop on ground were halted in the 1970ies and in 1977 the blast furnace, the Bessemer shop and all rolling mills were closed down for good.

In 1980 a new continuous caster was installed to supply feedstock for USINOR’s

wire rolling mill in Longwy.

In 1983 the steel foundry was closed down.

In 1985 the mill was split up into USINOR Acierie de Thionville and USINOR Forge de Thionville.

USINOR and SACILOR, the two largest steel groups in France were fusioned in 1986, now government owned.

The steel mill became part of Unimetal (the long product subsidiary of USINOR) while the forge became part of the USINOR/Cockerill owned rolling mill manufacturer Forcast.

The continuous caster was closed in 1994 and the steel mill was now taken over by Forcast.

Forcast was sold to the Swedish roller manufacturer Akers in 2001.

Akers still runs the 70 ton electric arc furnace, ingot casting and the 4000 ton forging press to produce ingots and forged rolls mostly for the steel industry.

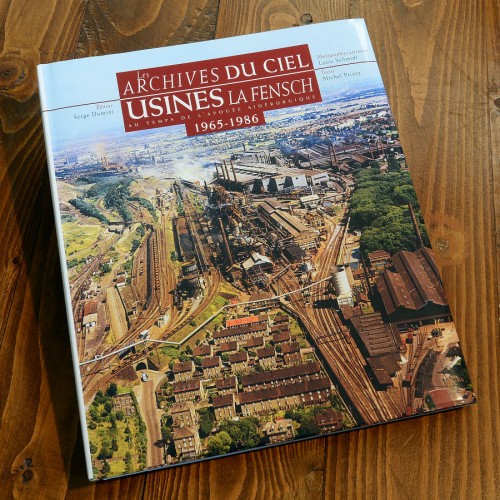

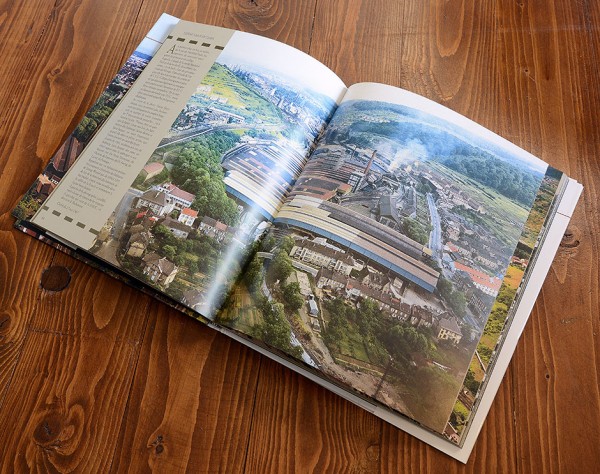

Usines La Fensch

A new book showing rare aerial views of the five steel and iron mills that once shaped the Fensch valley in Lorraine, France.

The quality of the large format images done by Louis Schmidt mostly in the 1960ies is predominantly extraordinary.

There ain’t much text so you don’t need to learn French to enjoy this book.

The book is published by Serge Domini, 120 pages, ISBN: 978-2-35475-064-0.

These books are usually out of print very fast and become quite expensive after a while.

Usine Saint Jacques

is the last rail mill in France.

The former Usine Saint Jacques in Hayange, France was founded by the De Wendel family in 1892. After the closure of the iron and steel production in 1972 the rail mill was outsourced by USINOR (successor of the De Wendel group) in 1994 now called Sogerail and owned by Unimetal.

In 1999 the mill was sold to the British Steel company from the UK to become part of the new Corus Group the same year.

Since 2007 the rail mill in Hayange is called Tata Steel Rail and part of the Indian Tata group.

Rails up to 108 meters in length can be produced. Billets for the rolling mill come from Tata’s steel plant in Scunthorpe, England.

Further viewing.

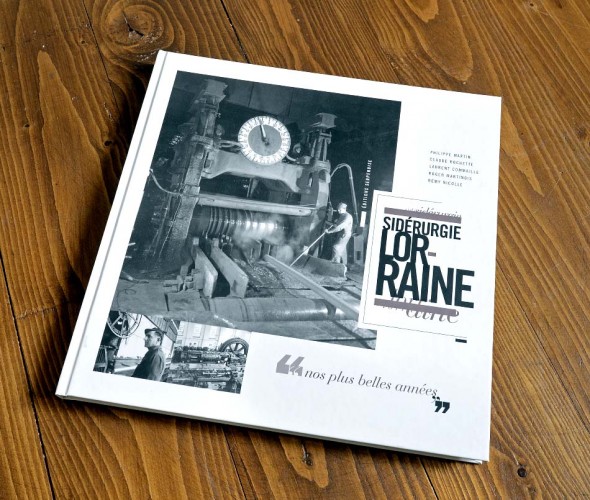

Sidérurgie Lorraine

A new book from Editions Serpenoise, who already published quite a lot about Lorraine steel making, shows rare and impressive images, in an overall good quality, from the Terre Rouge country.

After the book is 80%-photos it doesn’t matter much if you can’t read French.

The book has 150 pages and shows about 300 B/W images.

There are a few flaws like undated images, no real structure and some wrong captions, but overall it is worth buying.

Longwy

In the 1960ies the small town of Longwy, France (pop. 60000) still housed more than 20 blast furnaces. A unique density.

The mills were running on local iron ores of a rather poor quality that became uneconomical in the 1970ies with high quality iron ore shipped into Europe from overseas.

35 years ago, after the announcment of La Chiers’ closure, Longwy’s steel workers started their long and exceptional violent struggle to keep their jobs.

Since the closure of Arcelor’s wire rolling mill in 1998 there is no more steel industry in town.

Jean-Marie Ottelé site: www.industrie.lu is a unique source of information about the Terre Rouge (Red Earth) steel industry.

1: Cockerill-Ougrée-Providence

Founded: 1865.

Closed: 1987

2: Lorraine-Escaut

Founded 1835

Closed 1987

3: Hauts Fourneaux De La Chiers

Founded: 1881

Closed: 1979

4: Aciéries de Longwy

Founded: 1880

Closed: 1978

5: Hauts-Fourneaux Réunis de Saulnes et Uckange

Founded: 1872

Closed: 1991

369 Ton Steel Casting

Casting the lower beam of a forging press from four ladles at Industeel in Le Creusot, France.

Further images.

The first iron works the „Royal Foundry“ started production in Le Creusot, France in 1782.

In 1836 Adolphe und Eugène Schneider took over the foundry and made it into the “French Krupp”, a factory producing speciality steels, locomotives, large weapons and machinery.

In 1876 the largest steam hammer worldwide (100 ton) was installed at Schneider & Cie .The first hydraulik press starts production in 1890.

In 1920 more than 20000 people are employed in the mill’s blast furnaces, open hearth shops, rolling mills, forges, foundries and mechanical shops.

Iron production is closed down in 1940.

From 1949 on the mills in Le Creusot are named “Société des Forges et Ateliers du Creusot (SFAC)”.

In 1952 a 7500-ton hydraulic press (a reparation from Germany) was installed.

The first nuclear power plant equipment is produced in 1954.

In 1970 the SFAC joins the “Cie. des Ateliers et Forges de la Loire” to form “Creusot-Loire Industries“.

In 1984 Creusot Loire filed bancruptcy and the steel and rolling mills were taken over by USINOR.In 1998 the Creusot steel activities were merged with the Belgian Fabrique de Fer de Charleroi to form Industeel.

Industeel Le Creusot today runs a 100 ton electric arc furnace, a 4 meter heavy plate mill and a steel foundry.

Industeel is part of ArcelorMittal since 2006.

Le Creusot

The steel industry produced a few mythical places in it’s about 200 years of history.

Sheffield, Essen, Bethlehem and Terni belong to those and certainly Le Creusot in France.

The first iron works the „Royal Foundry“ started production in Le Creusot in 1782.

In 1836 Adolphe und Eugène Schneider took over the foundry and made it into the “French Krupp”, a factory producing speciality steels, locomotives, large weapons and machinery.

In 1876 the largest steam hammer worldwide (100 ton) was installed at Schneider & Cie .The first hydraulik press starts production in 1890.

In 1920 more than 20000 people are employed in the mill’s blast furnaces, open hearth shops, rolling mills, forges, foundries and mechanical shops.

Iron production is closed down in 1940.

From 1949 on the mills in Le Creusot are named “Société des Forges et Ateliers du Creusot (SFAC)”.

In 1952 a 7500-ton hydraulic press (a reparation from Germany) is installed.

The first nuclear power plant equipment is produced in 1954.

In 1970 the SFAC joins the “Cie. des Ateliers et Forges de la Loire” to form “Creusot-Loire“.

A new 11300-ton press was commissioned in 1979.

In 1984 Creusot Loire filed bancruptcy and the steel and rolling mills were taken over by USINOR to become part of Industeel later. The forge and mechanical shops became part of SFAR Steel and were taken over by AREVA, world’s largest manufacturer for nuclear power plant equipment, in 2006.

Today two forging presses, 7500-ton and 11300-ton, and two huge mechanical shops are in operation.

The old 7500-ton press will be replaced soon by a new 9000-ton press.

Further images at stahlseite.de

Rien ne va plus

According to the French newspaper Liberation AcelorMittal announced to shut down the hot end of it’s last integrated steel mill in Lorraine, France at Florange permanently.

The two remaining blast furnaces P3 and P6 that were idled in 2011 will not be restarted by AM.

ArcelorMittal is said to have offered the iron and steel making facilities at Florange to the French Government for one Euro to find a new owner within the next few month.