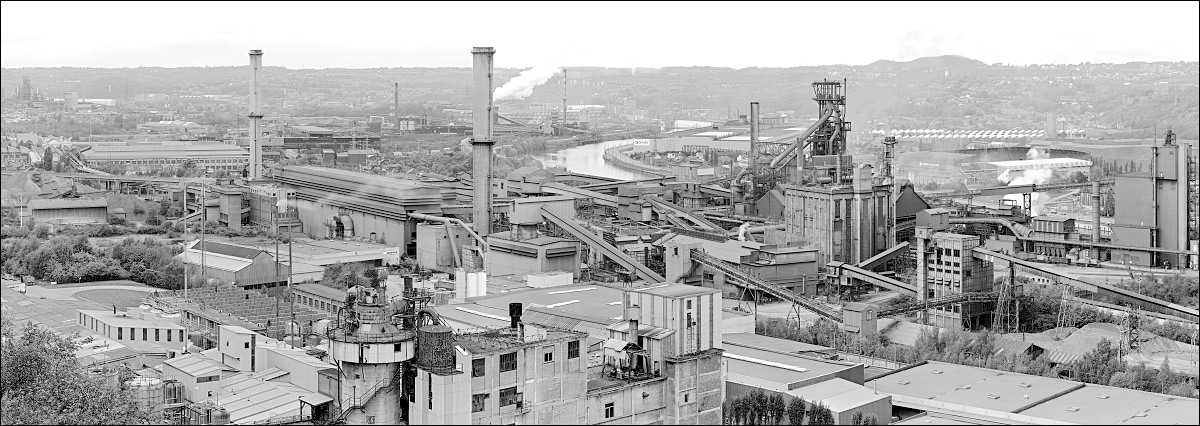

..was put into operation in May 1953 on ground of the Ougrée-Marihaye steel company in Belgium. It was a paneuropean research project sponsored by the ECSC and there was a second shaft furnace at the HOAG steel works in Oberhausen, Germany.

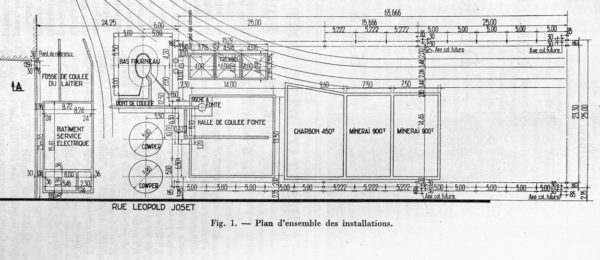

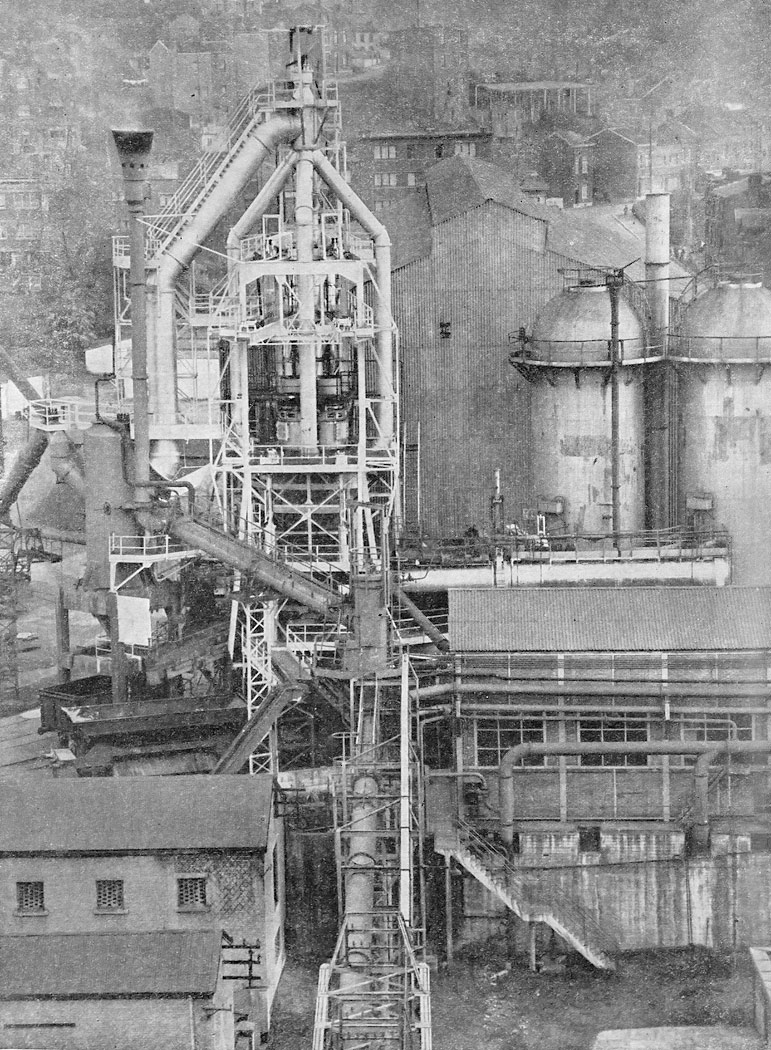

The Ougrée-furnace was quiet unusual not only by it’s size (just a 9 m tall shaft) but by it’s oval shaped hearth too.

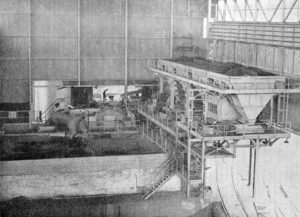

The furnace ran several campaigns to test different ore and coke burdens, oxygen injection etc. .

It’s inner and outer design was changed several times. From 1958 on the project was called AIRBO (Association International pour les Recherches de base au Bas fourneau d’Ougrée).

The Ougrée experimental blast furnace was closed down in 1971.