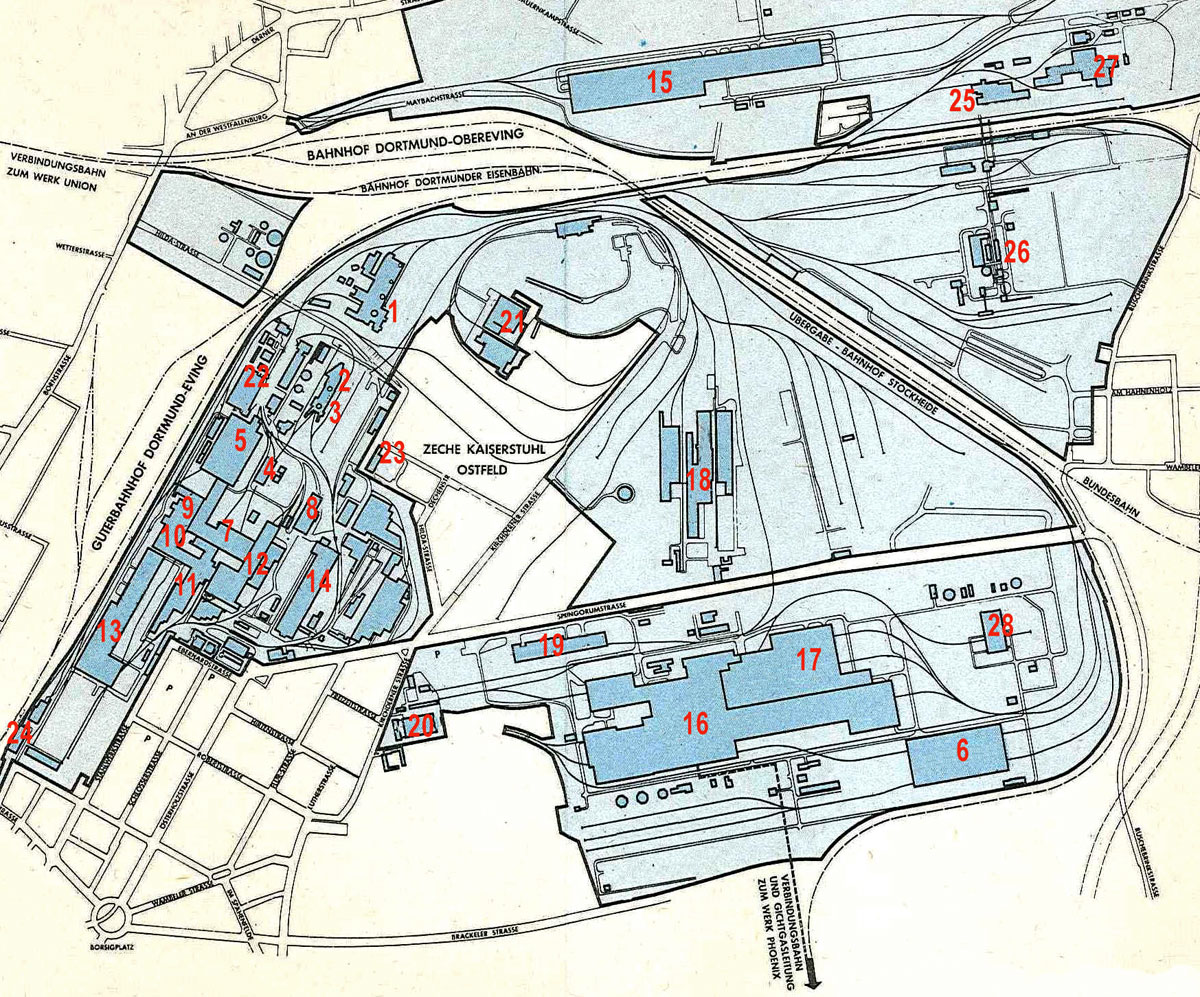

1: Hochofen IV. 1972-1999.

2: Hochofen VI. 1965-1976

3: Hochofen VII(alt) 1962-1976

4: Roheisenmischer

5: SM-Stahlwerk 2. 1912-1980

6: SM-Stahlwerk 3. 1956-1982

7: Thomasstahlwerk. 1928-1967

8: Elektrostahlwerk. 1955-1985

9: Blockwalzwerk. 1900-1983

10: Fertigstrasse (Schwere Profile). 1900-1968

11: Walzwerk III (Halbzeug). 1888-1966

12: Walzwerke IV/V. -1966

13: Kontinuierliche Halbzeugstrasse. 1955-1983

14: Walzwerk VIII. (Feinstahl). -1957

15: Feineisenstrasse. 1957-1983

16: Warmbreitbandstrasse. 1958-2001

17: Kaltwalzwerk

18: Drahtverfeinerung

19: Schwellenschweisserei

20: Lehrwerkstatt

21: Feuerfest- Steinfabrik

22: Gaszentrale

23: Sauerstoffanlage

24: Walzendreherei

25: Sinterbänder 1/2

26: Sinterband 3. 1961-

27: Zementfabrik

28: Lok-Werkstatt

Some images at Stahlseite.de .