Das Jahr 1966 brachte folgenreiche Veränderungen für die Hoesch Westfalenhütte in Dortmund mit sich. Am 1. Oktober übernahm ihr Mutterkonzern den Lokalrivalen, die Dortmund-Hörder Hüttenunion AG. Mit nun 5,4 Mio. Jahrestonnen wurde Hoesch zum zweitgrößten Stahlproduzenten in Deutschland und die Westfalenhütte eine Zweigniederlassung der Hoesch AG Hüttenwerke.

Das Jahr 1966 brachte folgenreiche Veränderungen für die Hoesch Westfalenhütte in Dortmund mit sich. Am 1. Oktober übernahm ihr Mutterkonzern den Lokalrivalen, die Dortmund-Hörder Hüttenunion AG. Mit nun 5,4 Mio. Jahrestonnen wurde Hoesch zum zweitgrößten Stahlproduzenten in Deutschland und die Westfalenhütte eine Zweigniederlassung der Hoesch AG Hüttenwerke.

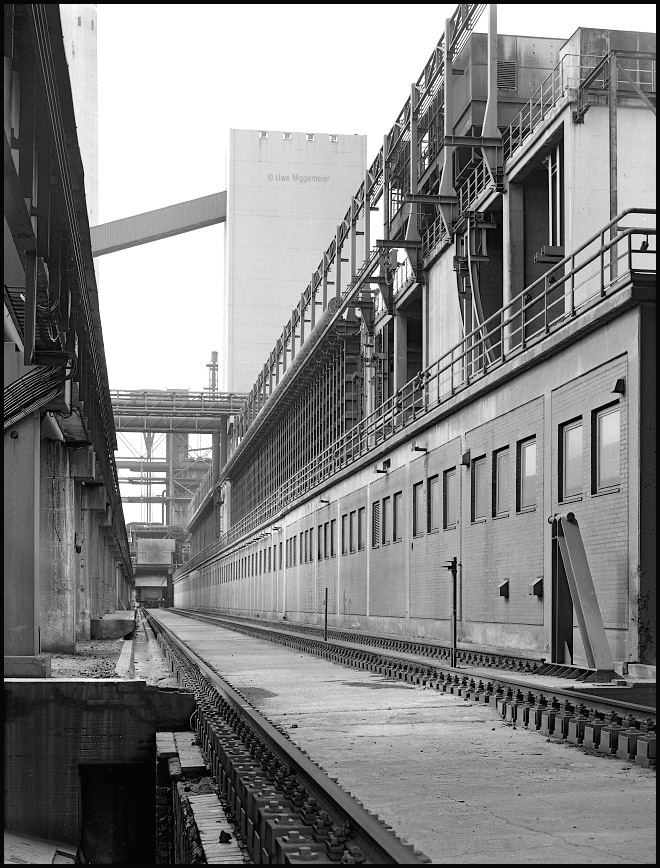

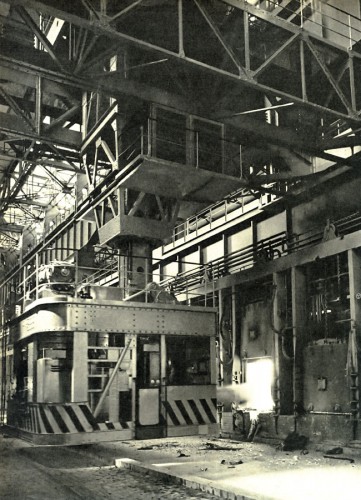

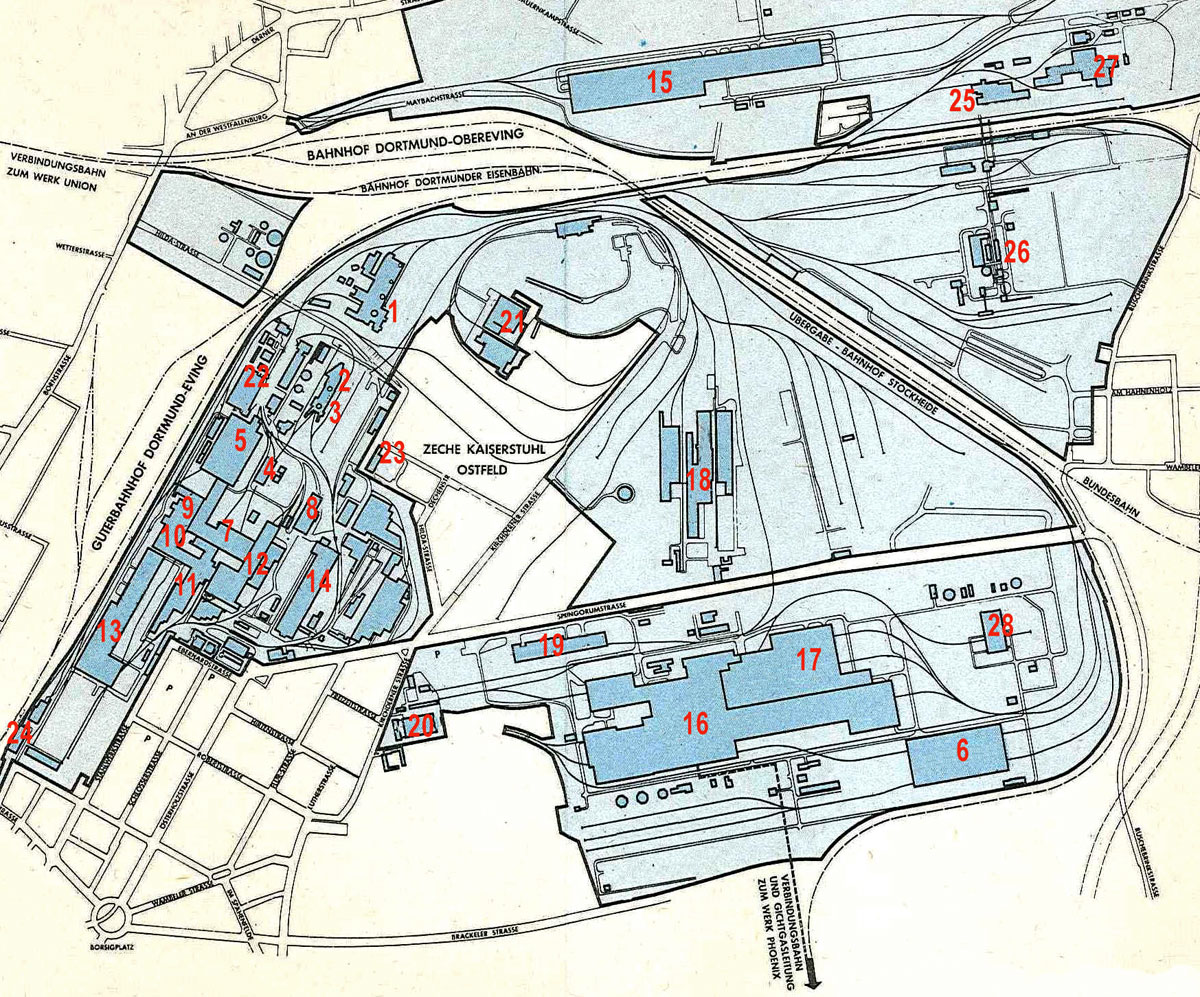

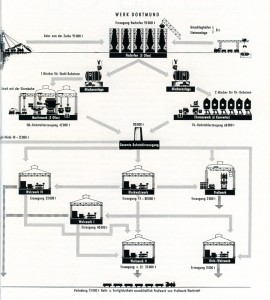

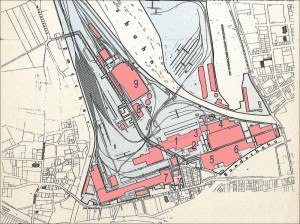

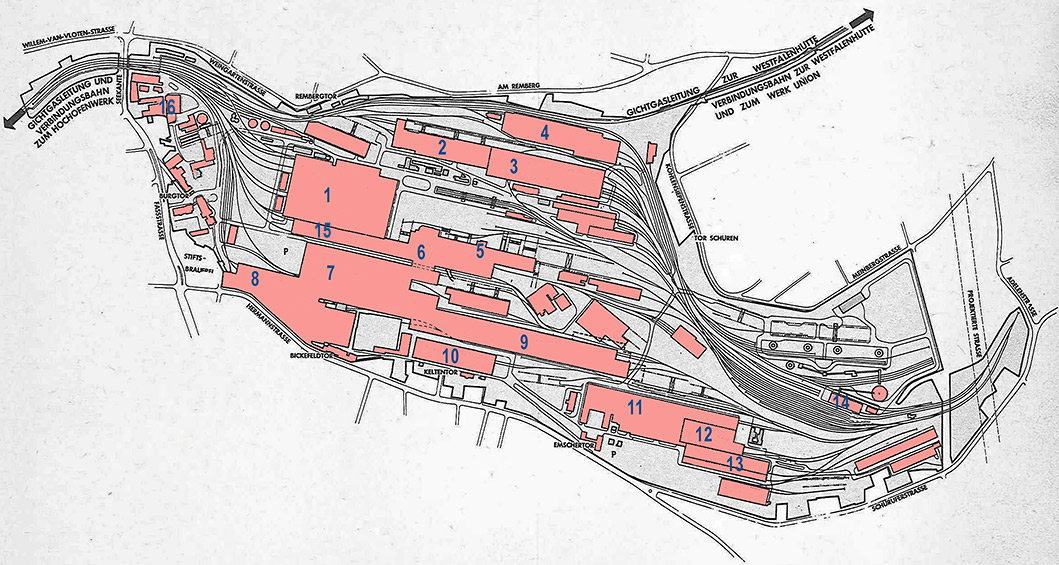

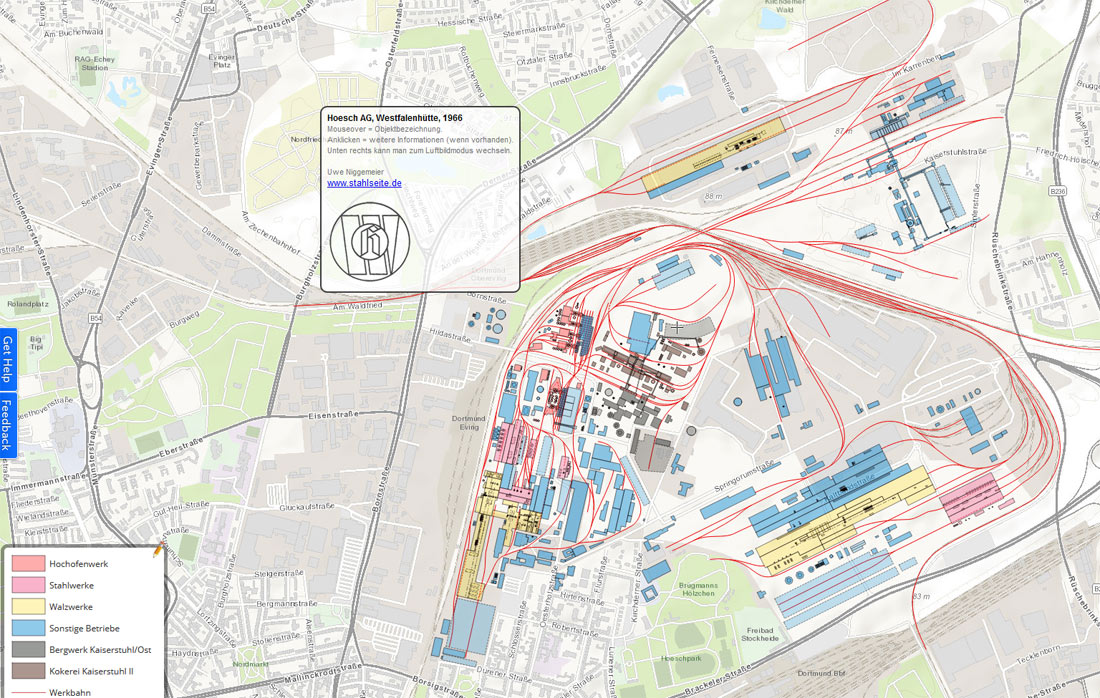

Schon im darauf folgenden Jahr begann die Verlagerung von Produktion an die neuen Standorte Hörde und Union. Das Thomaswerk und div. Profilstraßen auf der Westfalenhütte wurden stillgelegt. Gut zu erkennen sind in der Karte die großen Komplexe der neuen kontinuierlichen Walzwerke und die dafür zur Verfügung stehenden immensen Erweiterungsflächen im Nordosten des Stammwerks. Nur die kont. Halbzeugstraße musste weil sie in einer Hitze mit der vorhandenen Blockstrasse arbeitete im Bereich der alten Hütte errichtet werden. Dafür wurde 1954 das alte Blechwalzwerk geschlossen und abgerissen.

Im Juni 1966 wurde die Zeche Kaiserstuhl stillgelegt, damit endete nach 75 Jahren die Steinkohlenförderung auf der Hütte. Die Kokerei Kaiserstuhl 2 ging 1969 an die Bergbau AG Dortmund (RAG) und wurde im Dezember 1991 geschlossen.

Am 30.9.1966 beschäftigte die Westfalenhütte 15862 Mitarbeiter.

Die weitere Entwicklung des Standorts hatte ich bereits hier beschrieben.

Dank an das thyssenkrupp Konzernarchiv, das Stadtarchiv Dortmund und das SMS Group Unternehmensarchiv für die Unterstützung bei der Erstellung dieser Karte.