Tag Archives: USA

The Last Open Hearth In The U.S.

© Chris Dunker (Dunker Imaging)

was closed down in December 1991 at Geneva Steel in Utah. The end of an era for a nation that, in 1970, still produced nearly 40% of it’s raw steel out of open hearth furnaces.

The Geneva OH-shop contained ten 340 ton furnaces first tapped in 1944 and upgraded in between 1957 and 1964.

They were replaced by two 225 ton Q-BOF vessels originally installed at Republic Steel’s (later LTV Steel) South Chicago works in 1991.

For an unknown reason the Geneva Steel company, the successor of U.S. Steel, left the open hearth shop standing until they finally went bancrupt in 2002 and the mill was dismantled in 2004.

Large portions of the mill (caster, plate and strip rolling mill) were sold to Chinese steel maker Qindago Steel.

In 2004 Chris Dunker was allowed to document the demolition of the mill with his camera.

Part of the work can be seen in his book: “Dismantling Geneva Steel”.

California Furnaces

The least thing one would expect more than 2000 miles west of the rustbelt and just 50 miles out of Hollywood is a fully integrated steel mill.

But it was there, built in 1942 by Henry J. Kaiser on a former hog farm and ,mostly ,dismantled in the late 1980ies.

In the early 1940ies Kaiser Industries were in search for a steel plate supply for their nearby Richmond shipyards where more than 700 vessels, mostly “Liberty Ships” were built during WWII.

In 1942 ground was broken in Fontana and by 1943 a coking plant, one blast furnace (“Big Bess”) with a capacity of 1200 tons/d and an open hearth shop were under fire.

A 148″ plate mill was added in 1943 and the 86″ hot strip mill started in 1950.

In it’s heyday the mill ran four blast furnaces(hearth diameter 8,7 -8,9 meter) and installed the second BOF steel making shop in the U.S. as early as 1955.

In the 1960ies the location 50 miles away from the coast (imposed by the U.S. Army) at the so called “Inland Empire” became an increasing problem with all raw materials having to be hauled in by rail.

In a last attempt to make the plant competitive a new BOF shop and a continuous caster were built in 1978 to be closed down for good already in October 1983.

Kaiser Steel filed bancruptcy and the plate and hot strip rolling mills were taken over by California Steel Industries in 1984, supplied with slabs from overseas.

The plate mill was sold to the Oregon Steel Company in 1989 and abandoned in 1994.The 86″ hot strip mill is still active.

The remaining iron and steel making facilities were occasionally used by nearby Hollywood studios as a film set (Terminator2) and later dismantled.

The BOF shop was bought by the Capital Iron & Steel Co and shipped to China in 1993.

The ground is now overbuild by a car race track.

Nice historical feature.

Vintage image #8

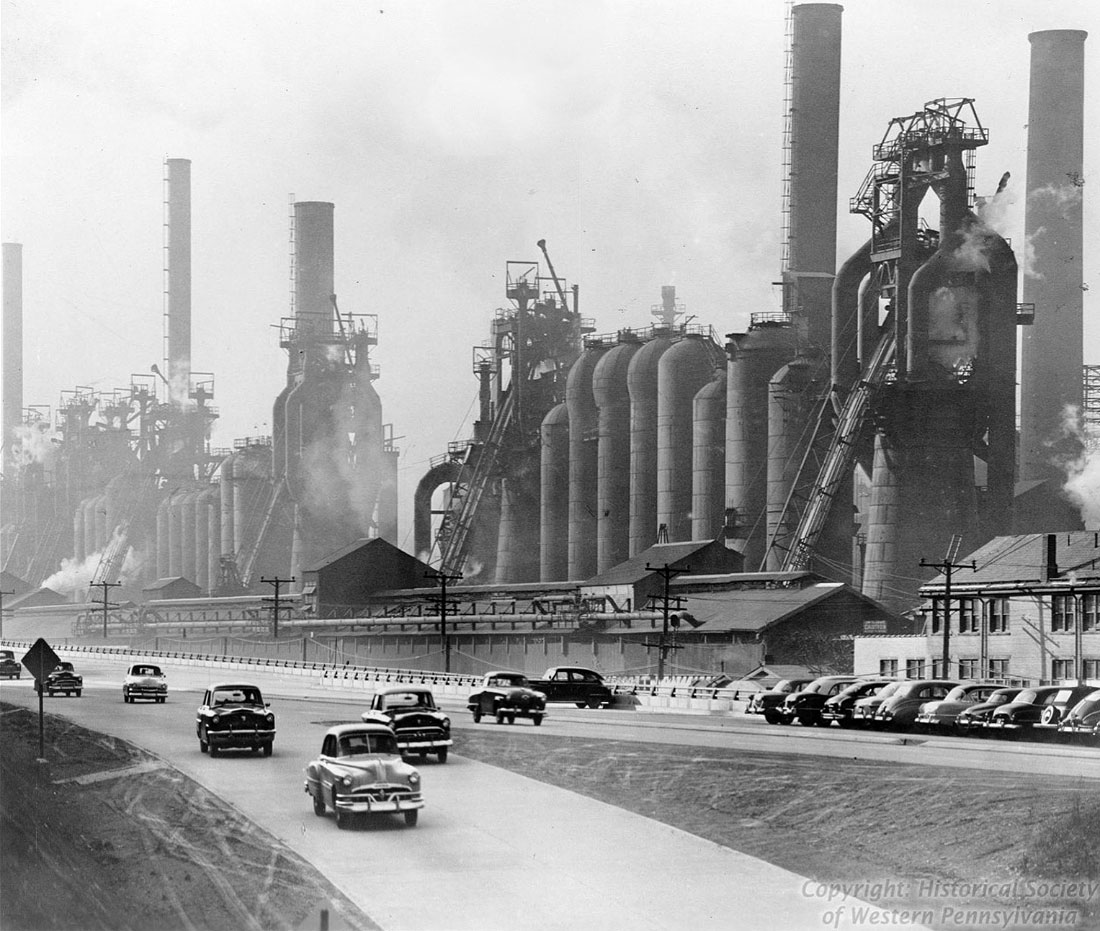

The Carnegie Steel Ohio works on the banks of the Mahoning River around 1910.

This mill became part of U.S. Steel later and was closed in 1979.

Starting with the “Black Monday” in September 1977, the closure of Youngstown Sheet And Tube, the once thriving valley of steel was gutted within just one decade.

A recommendable book telling the story of this decline is John Russo’s “Steeltown U.S.A. – Work And Memory In Youngstown” published by the University Press Of Kansas.

Gone In June

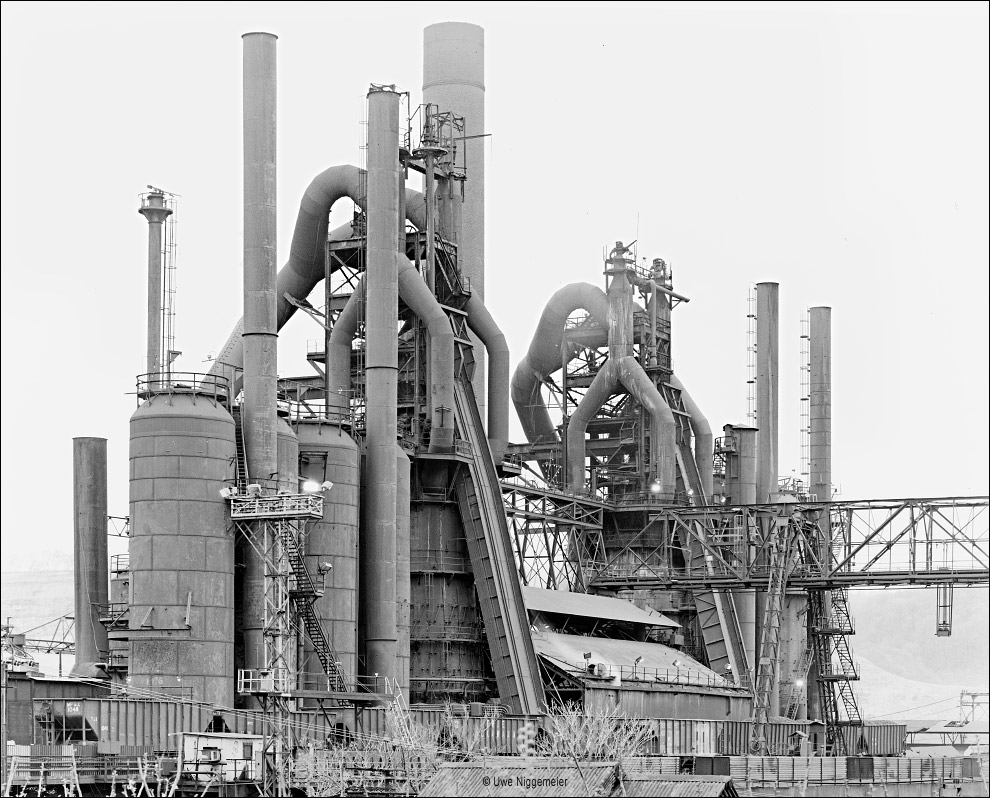

The blast furnaces No.1&2 at Wheeling Pittsburgh’s former Steubenville North plant will be chopped down by an implosion demolition in June.

Furnace No.1 was built by the La Belle Iron Works in 1901. It was in operation until May 2005 when it was the oldest active blast furnace in the U.S. . It has a hearth diameter of 7,5 meters and a working volume of 1050 m³.

The No.2 furnace was built in 1904 and idled earlier.

The image was done in April 2004.

Vintage Image #6

Vintage Image #4

The Vintage Image #3

Sparrows Point To Be Scrapped

Natrona, Pennsylvania

A small, former, industrial village on the banks of the Allegheny River.

In the background the remarkable Allegheny Ludlum melt shop from 1966 that hosts a huge 114″ (2,90 meter) hot blast cupola furnace, two 80 ton BOF vessels and three 70 ton induction furnaces. The cupola furnace produced up to 65 tons of hot metal per hour and was closed down in the late 1970ies to be replaced by the induction furnaces.

The melt shop was shut down in 2010 and is now demolished.