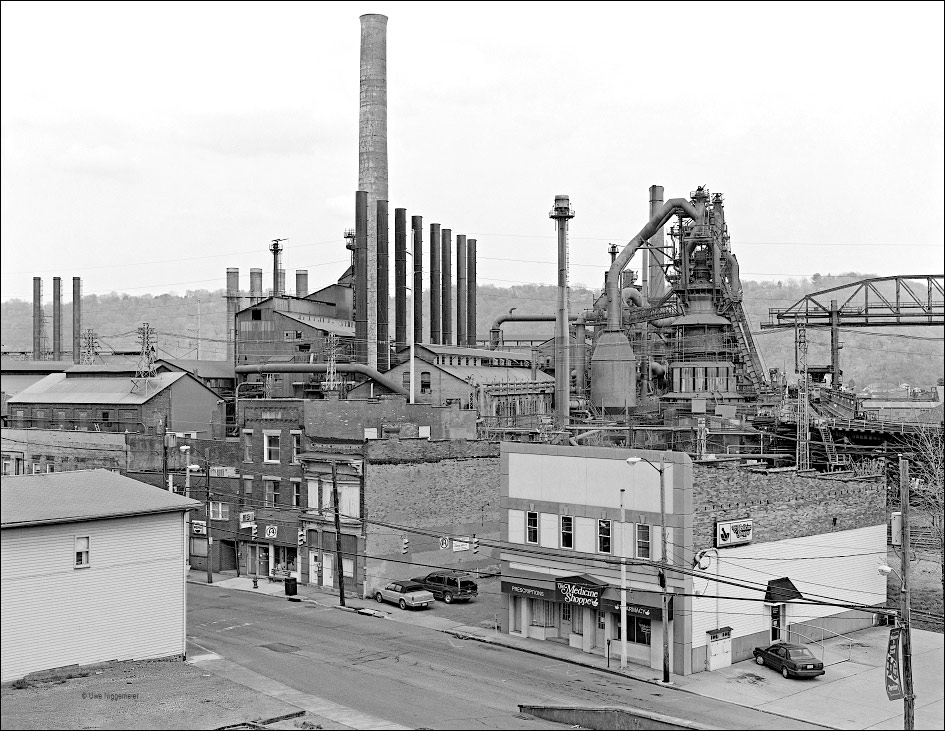

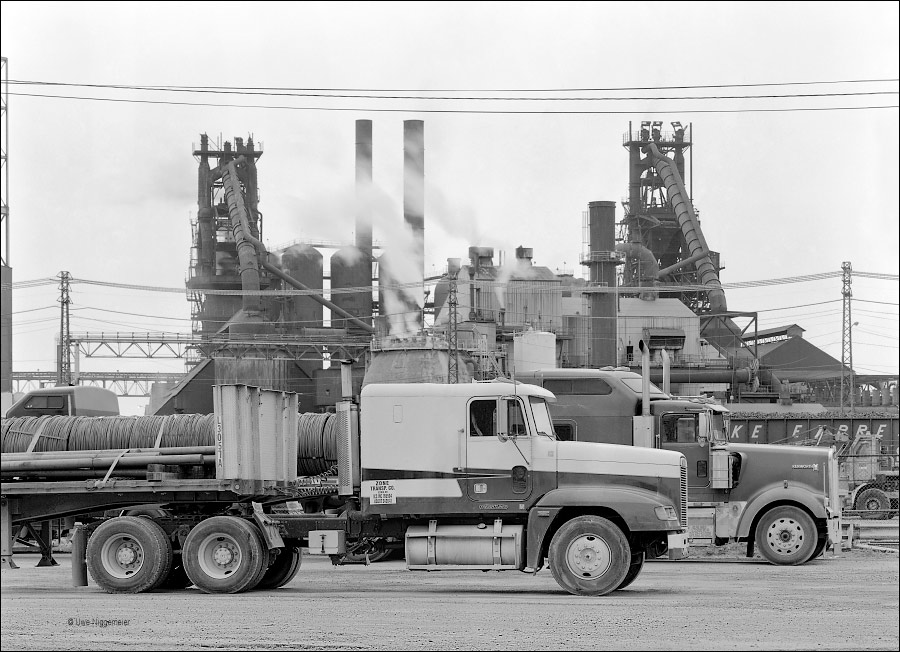

Image shows the Bethlehem Steel Mill in Lackawanna, NY south of Buffalo at the Lake Erie shoreline probably in the late 1960ies.

Foreground shows the 535 coke ovens along the dock, behind are the seven blast furnaces and (right hand side) the open hearth melt shop (35 furnaces).

The background is also attractive:

Right from the centre we can see National Steel’s Hanna Furnaces and far away in the middle Republic Steel’s Buffalo works.

Lackawanna was closed down in 1983.

- BF A: Ø 21’3” (6,47 m)

- BF B: Ø 21’3” (6,47 m)

- BF C: Ø 28’0” (8,53 m)

- BF F: Ø 26’0” (7,92 m)

- BF G: Ø 27’0” (8,22 m)

- BF H: Ø 29’0” (8,83 m)

- BF J: Ø 29’11” (9,11 m)