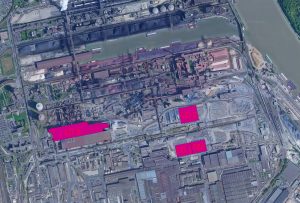

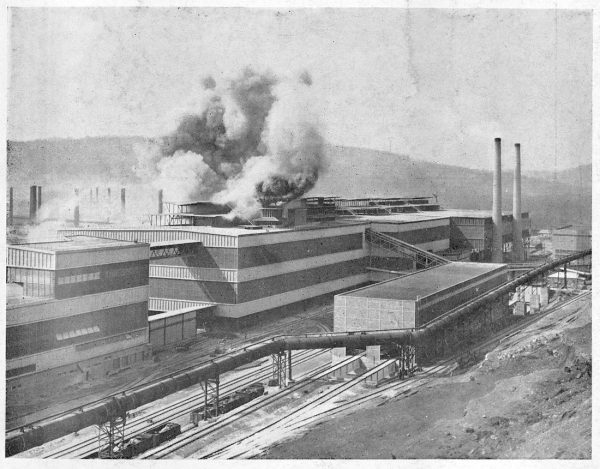

Zwischen dem 30.7.1973 und dem 21.12.1977 betrieben die Vereinigten Österreichischen Eisen- und Stahlwerke (VÖEST) in Linz als einziges Hüttenwerk in Europa drei LD-Stahlwerke parallel.

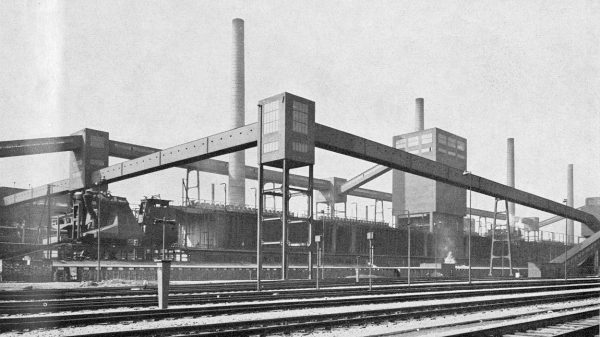

Das LD-Stahlwerk 1, das erste weltweit, ging im November 1952 mit zwei 30 t Konvertern in Betrieb und war an der Westseite an das existierende SM-Elektrostahlwerk angebaut worden. 1956 wurde dort ein dritter Konverter aufgestellt.

Im August 1959 nahm die VÖEST ihr zweites LD-Stahlwerk etwa 130 m nördlich des ersten in Betrieb. Hier arbeiteten die Tiegel 4 und 5 (50 t) 1968 wurde auch dort ein dritter Konverter installiert.

Im Juli 1973 ging schließlich das LD-Stahlwerk 3 in Produktion. Zunächst mit nur einem 140 t Konverter.

Jetzt betrieb die VÖEST in Linz drei LD-Stahlwerke, ein Siemens-Martin Stahlwerk (mit nur noch einem 200 t Ofen), ein Elektrostrahlwerk (mit zwei 20 t Öfen) und ein LD Versuchsstahlwerk mit einem 5 t Konverter (im SM-Stahlwerk).

1976 legte man dann den verbliebenen SM-Ofen und den Versuchskonverter still und im LD 3 wurde der 2. Konverter (Tiegel 8) angefahren.

Am 21.12.1977 endete die Produktion (mit nur noch einem Tiegel) im ältesten LD-Stahlwerk der Welt.

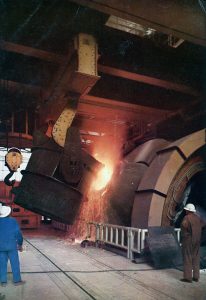

Im März 1988 erreichte das LD 3 seine endgültige Ausbaustufe mit der Inbetriebnahme des dritten Konverters (Tiegel 9, 140 t).

Das E-Stahlwerk legte man 1989 still und ein Jahr später endete die Produktion im LD 2.

Damit war im Grunde der heutige Zustand bei der Stahlerzeugung in Linz erreicht.