in La Louviere, Belgium where torn down 15 years ago in between August 2003 and September 2004.

The line of 6 units showed the entire development of blast furnace technology in the 20th century.

Blast furnace 1, Ø 4,5 m, 1913.

Blast furnace 2, Ø 4,5 m, 1913.

Blast furnace 3, Ø 4,5 m, 1930.

Blast furnace 4, Ø 4,5 m, 1939.

Blast furnace 5, Ø 5,5 m, 1958.

Blast furnace 6, Ø 6,5 m, 1972.

Tag Archives: Belgium

Thin Plate Mill

The rolling mill in Clabecq, Belgium goes back to the old Forges de Clabecq, founded in 1850.

After the closure of it’s blast furnaces and steel production in 2002 the site was taken over by NLMK from Russia in 2006.

The unique thin plate mill includes a quarto roughing stand and four continuous finishing stands and was built in 1971.

Photos now at my website.

Steel Production In The Liege Basin Ceased

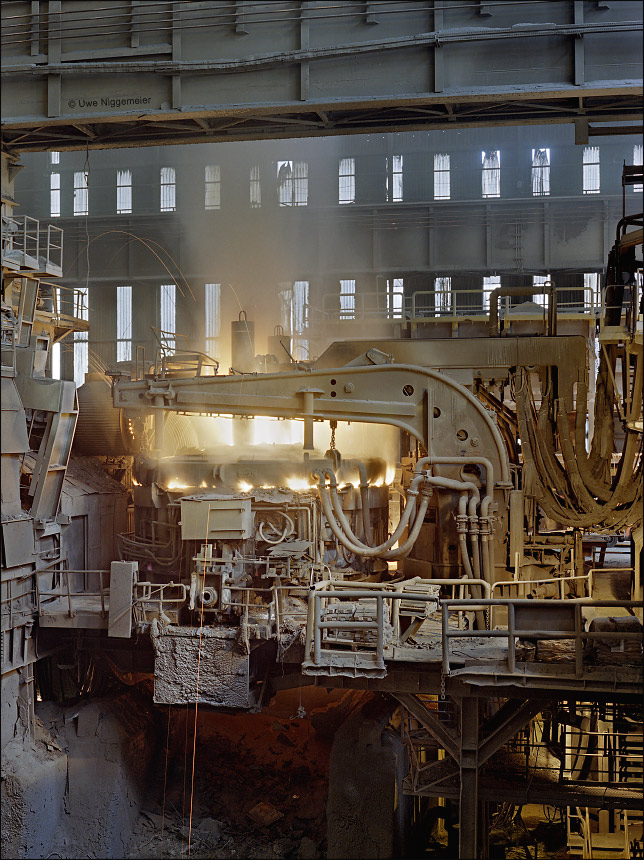

Engineering Steel Belgium (ESB) in Seraing, Belgium announced that it will finally close down it’s steel making and casting facilities. Production is already down for two weeks.

The 70 ton electric arc furnace and the world’s largest round strand caster were built in 1972 by Cockerill to provide blooms for the Tubemeuse Pilger rolling mill across the river.

Tubemeuse was founded in 1911 under the name S.A. des Usines à Tubes de la Meuse. It was later taken over by Cockerill and went bancrupt in 1988. The mill carried on under the name New Tubemeuse until it filed bancruptcy again in 1993. The tube rolling facilities were closed down this time and the melt shop was sold to the Ellwood Steel company from Pennsylvania.

In 2009 the German GMH group bought the site.

Further viewing.

Five days ago ArcelorMittal already announced the closure of it’s coking plant in Seraing within the next two weeks. The attempt to sell the site (built in 1957) to the U.S.-based Oxbow company had failed.

Société Carolorégienne de Laminage

CARLAM (Société Carolorégienne de Laminage), the wide hot strip rolling mill in Chatelet, Belgium was built in 1976 on the banks of the Sambre river by the Hainaut-Sambre steel company.

It became the third wide hot strip mill in Belgium (besides Espérance-Longdoz’ Chertal site and Sidmar in Ghent).

The mill was supplied with slabs from Hainaut’s BOF shop (built in 1971) in nearby Montignies.

In 1980 Hainaut-Sambre merged with the Thy-Marcinelle steel company located in another suburb of Charleroi to become the largest steel producer in the Sambre valley.

Only one year later Hainaut-Sambre joined the Cockerill company from Liege, Belgium to form Cockerill-Sambre.

In 1982 a second walking beam furnace and a sixth finishing stand was installed at Carlam.

The blast furnaces and the BOF steel making in Montignies were closed in 1985. Slabs were provided by Cockerill Sambe’s OBM steel plant in Marcinelle (built in 1976) from now on.

A seventh finishing stand was commissioned at Carlam in 1989.

Cockerill-Sambre became part of Arcelor in 2002.

After the integrated steel production at Marcinelle was sold to the DUFERCO steel group in 2004 (now called CARSID) a new stainless steel melt shop was built in 2004 in Chatelet next to the Carlam rolling mill.

Carlam was renamed Carinox and became part of Arcelor’s stainless steel branch Ugine & ALZ.

The stainless branch of ArcelorMittal (who merged in 2007) was spinned off under the new name Aperam in 2010.

The newly installed 160 tons electric arc furnace is one of the largest in Europe. It supplies raw steel to a 180 ton AOD converter for the transformation to stainless steel.

The steel is then casted into slabs weighing 30 tons each.

The wide hot strip mill processes slabs both from Chatelet and the second Aperam melt shop in Genk, Belgium.

More images at Stahlseite.

Liege Coking Plant Might Survive

No More Steel From Gustave Boël

Last night the steel workers at the DUFERCO, La Louviere plant in Belgium accepted the closure of their plant and a redundancy package offered by the company.

The electric arc steel making shop and the wire rolling mill will be closed and eventually mothballed.

Only the strip rolling mill, owned by the Russian NLMK group will survive.

The mill in La Louviere was founded in 1853 as “Fonderies et Laminoirs Ernest Boucquéau”.

When Ernest Boucquéau died in 1880 he inherited his steel mill to his plant manager Gustave Boël.

Based on local coal deposits a large integrated mill grew on the banks of the Charleroi-Bruxelles shipping canal.

A Thomas-converter melt shop was installed in 1903 and in 1912 the construction of two modern blast furnaces began.

After destruction in the first world war the mill was restarted in 1924 with two blast furnaces, a coke plant, a Thomas-converter steel making shop, an open hearth shop, several rolling mills a foundry and a forge.

Two new blast furnaces were built in between 1930 and 1937.

In 1967 a new BOF shop containing two 85 ton LD-AC converters was completed.

A third converter was installed in 1969.

Blast furnace no. 6 was built in 1972.

The coking plant, built in the 1930ies, was closed in the 1980ies and than dismantled.

In 1993 new 85 ton electric arc melt shop was installed.

The Usines Gustave Boël (UGB) were partly taken over by the Hoogovens steel group from the Netherlands in 1997. In the same year the last blast furnace and the BOF shop are closed down.

In 1999 the DUFERCO steel group acquires the plant.

In 2003 the unique row of blast furnaces from four generations (1912, 1930,1958,1972) was demolished.

In 2011 the Russian NLMK group took over the flat rolling activities from DUFERCO who kept the steel making and wire rolling part.

Further images at Stahlseite.

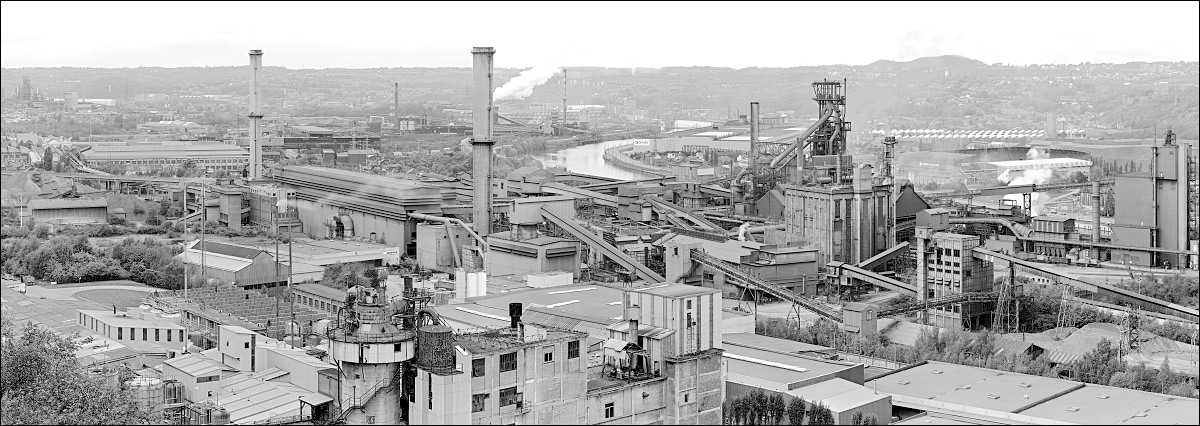

The End Of Another Steel Valley

Today the ArcelorMittal steel company announced the closure of the majority of it’s remaining steel production sites in the Meuse valley near Liege, Belgium.

About 1300 of the remaining 2100 steel workers in the valley will loose their jobs.

Apart from the hot strip mill and the coking plant a cold rolling mill and two galvanisation lines will be closed for good.

The liquid phase steel production was already closed in October 2011.

The Meuse valley around Liege is one of the cradles of the European industrialisation.

Closed for good

The AFV Beltrame Group from Italy declared on monday that they will shut down their bar rolling mills in Monceau s. Sambre, Belgium and in Esch-Schifflange, Luxembourg definitly.

Images of the Laminoirs Du Ruau and the Train A Lamines Marchands.