Photos of Swedens only wide hot strip mill now on my

website.

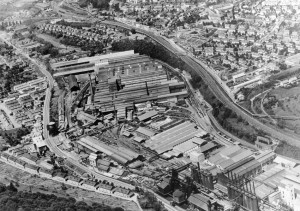

The steel works in Borlänge, Sweden were built in 1872 by Stora Kopparbergs Bergslags AB and named Domnarvets Jernverk.

A blast furnace was installed in 1878 and in the following years the mill became one of Sweden’s largest steel producers.

In the late 1940ies Professor Bo Kalling developed his rotating KALDO (KAlling-DOmnarvet) converter in Borlänge. The first 30 ton vessel became operable in 1954 capable of converting Sweden’s high phosphorous iron into high quality steel.

Though the process competed against the LD-process from Austria for a while it disappeared later due to it’s high maintenance costs especially for the lining.

The last Kaldo converter at the Domnarvets works was shut down, together with the four remaining blast furnaces, in 1981. Three years before Borlänge had become part of the newly established Svenskt Stål Aktiebolag (SSAB).

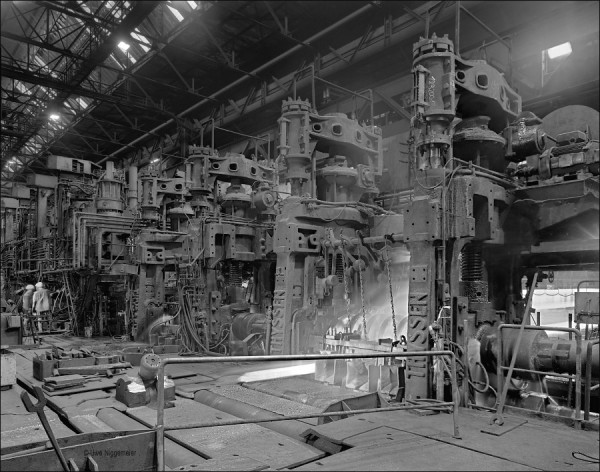

In 1989 steel making (now in an electric arc furnace) ended at Domnarvet and only the 1650 mm hot strip mill, installed in 1961 by the Sack company from Düsseldorf, Germany, continued to operate.

It was constantly modernised and obtained a new roughing stand from SMS in 1999.

Borlänge is now part of SSAB’s EMEA (Europe, Middle East, and Africa) division and receives it’s primary material in the form of slabs from SSAB’s integrated works in Lulea and Oxelösund.