…what you are shooting. At least in Steel Industry Photography.

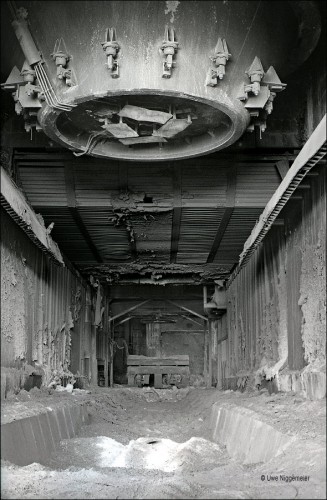

One of my first steel plant interiors. Krupp Rheinhausen in 1997 and no clue what that “silo” above might be.

So I never went upstairs to see the two 320 ton BOFs, the second largest in Germany. The BOF shop was blown up in 1999.

Category Archives: Ruhr-West

Vintage Image #7

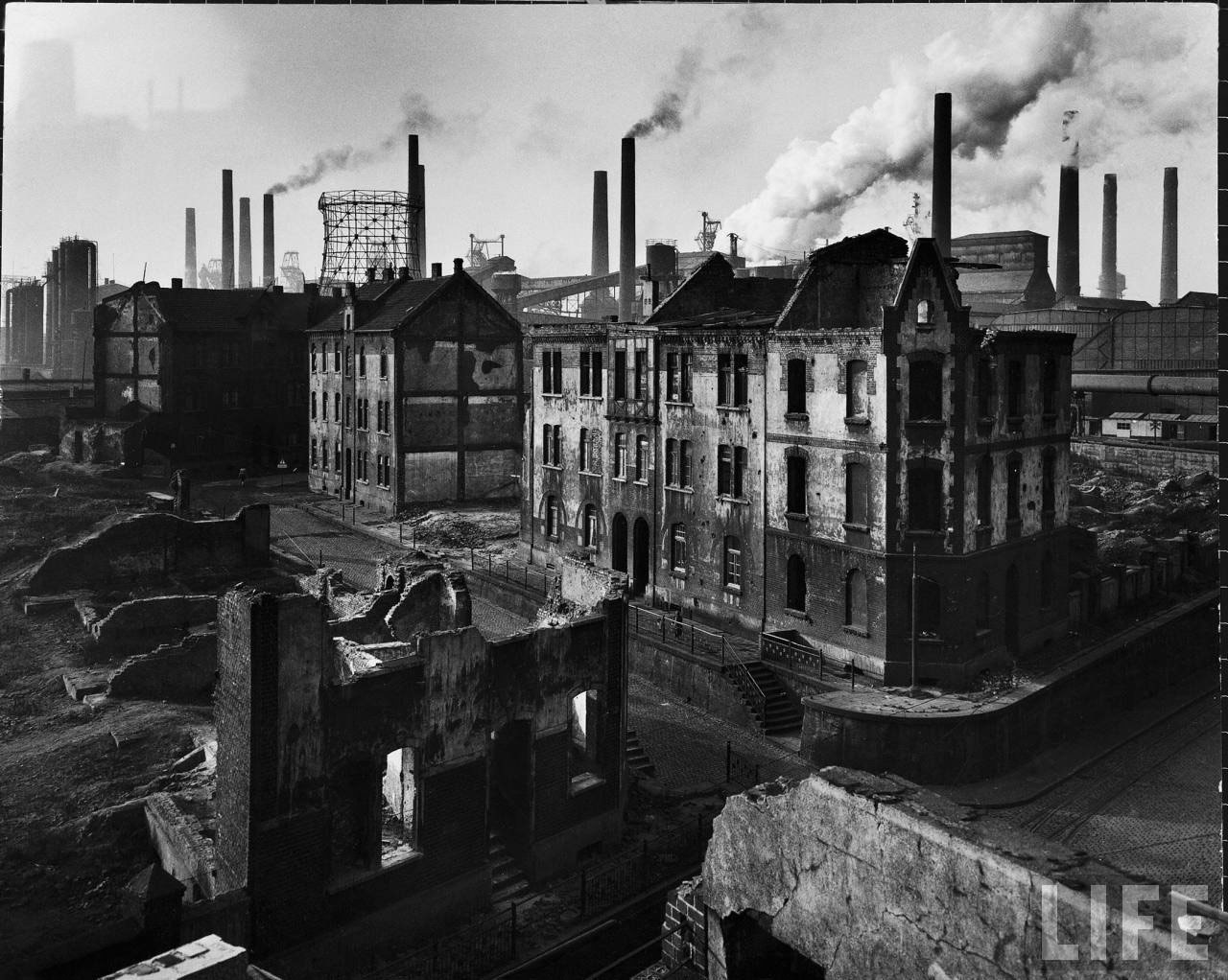

The image done in 1953 shows the August Thyssen Hütte steel works in Duisburg Hamborn, Germany.

The furnaces shown are, left to right: 7,6,5,4,3,2 . Number one is hidden by the steam cloud from the attached coking plant August Thyssen. Blast furnaces 8 and 9 are to the left and not included. In the center of the image the headgear of coal mine Friedrich Thyssen,shaft 7 is to be seen.

Some more recent images of the mill at Stahlseite.

Fritz Schupp, 1957

The famous German industrial architect built this melt shop in 1957 for Phoenix Rheinrohr in Duisburg, one of the largest German steel companies of that time. It was equipped with three Thomas converters and one modern oxygen converter.

The building underwent several changes over the years especially when it was transformed into a BOF shop in 1969.

Nowadays the ArcelorMittal Ruhrort plant runs a steel making shop with two 140 ton BOF vessels (and one in reserve), two continuous casters and a two stand billet mill. Hot metal comes from the ThyssenKrupp steel company in Duisburg via bottle cars.

Further images on my site.

Grey Iron Casting

Founded in 1921 the Metallwerk Fritz Kleinken is a medium size foundry on the northern rim of the industrial Ruhr-Area in Germany.

It produces grey iron and nodular iron castings up to 30 tons a piece from two cupola and two induction furnaces.

Fritz Kleinken employes 180 people.

Further images at Stahlseite.

The vintage image #1

Bruckhausen, the former working class neighbourhood that adjoins to the vast August Thyssen Hütte steel mill in Duisburg, Germany, in the early 1950ies.

Ironically Bruckhausen looks much the same nowadays again because the ThyssenKrupp steel company and the administration of Duisburg have decided to tear it down in favour of a huge park (Article, in German).

Guntram Walter did some impressive images of this ghost town.

Demolition of blast furnace no. 4 started

The blast furnace Hamborn no. 4 at the ThyssenKrupp mill in Duisburg will be gone by next summer.

The furnace was built in 1964 replacing the old no. 4 that had been partly dismantled for reparation. It has a hearth diameter of 10,70 meters and a working volume of 2030m³.

The new furnace was the first one worldwide to be equipped with a bell less charging system. And it was the first in Germany to use coal powder injection.

Until May 2008, when the furnace was mothballed as a back up furnace it produced 43 mio. tons of iron.