Anläßlich ihres 20-jährigen Jubiläums wurde die GWA noch als weitsichtige und lohnende Investition bezeichnet, nun aber, nur ein Jahr später, wird sie stillgelegt.

Anläßlich ihres 20-jährigen Jubiläums wurde die GWA noch als weitsichtige und lohnende Investition bezeichnet, nun aber, nur ein Jahr später, wird sie stillgelegt.

Als die GWA im April 1999 in Betrieb genommen wurde war sie die erste Anlage ihrer Art in einem integrierten Hüttenwerk weltweit.

Offenbar hat sich die Erzeugung von Breitband in einer Hitze in diesem Rahmen aber nicht bewährt denn Thyssen-Krupp Steel kündigt an die Anlage zu einer Warmbreitbandstrasse klassischer Bauart umzubauen.

Category Archives: Ruhr-West

Karte: Niederrheinische Hütte AG, Duisburg, 1964.

Die 1851 gegründete Niederrheinische Hütte die ab 1904 zum integrierten Hüttenwerk ausgebaut worden war spezialisierte sich nach dem 2. Weltkrieg und der Demontage des Blechwalzwerks auf die Herstellung von Drähten und Stabstahl.

Die Roheisenerzeugung wurde zwischen 1955 und 1959 durch den Neubau der Hochöfen 1 und 3 modernisiert. Der noch von 1937 stammende Ofen 2 konnte 1959 stillgelegt werden. Der Hochofen 3 war mit einem Gestelldurchmesser von 5,5 m, einem Volumen von 725 m³ und einer Profilhöhe (Gestellboden-Gasfang) von 22,25 m der größte Hochofen der NH. 1956 installierte die NH als erstes Hüttenwerk in Deutschland eine Gichtgasturbine zur Erzeugung von Strom und Hochofenwind. Trotzdem belegte die Hütte mit einer Jahresproduktion von circa 400.000 t (1962) nur den 20. Rang unter den deutschen Roheisenerzeugern.

1958 wurde die 1913 erbaute Erzröstanlage mit Handbeschickung (die letzte ihrer Art in Deutschland) durch eine moderne Sinteranlage mit einem 2×30 m Dwight-Loyd Band ersetzt.

1955 übernahm die August-Thyssen-Hütte die Aktienmehrheit der Niederrheinischen Hütte und ab 1958 lieferte die NH Roheisen im Flüssigtransport an das Siemens-Martin-Stahlwerk der ATH.

Nach der Übernahme der Phoenix-Rheinrohr AG durch die ATH in 1964 wurden die Roheisenaktivitäten der Thyssen-Gruppe neu geordnet und auf die Standorte Hamborn, Ruhrort und Meiderich konzentriert.

Der Hochofen 1 der NH wurde daher im August 1965 heruntergefahren und der Ofen 3 als letzter am 23.9.1966 stillgelegt. Die Sinteranlage wurde noch bis Ende der 60er Jahre an die Hüttenwerke Rheinhausen verpachtet.

Das SM-Stahlwerk der NH stammte aus dem Jahr 1906 und wurde bis 1963 mit sieben und danach mit sechs Siemens-Martin-Öfen betrieben. In den 1950er und frühen 1960er Jahren fand eine schrittweise Modernisierung und Umstellung von Generatorgas- auf Ölfeuerung statt. Das SM-Stahlwerk wurde am 5.11.1966 stillgelegt.

1964 betrieb die Niederrheinische Hütte noch sechs Walzstrassen:

Eine Blockstrasse und eine Knüppelstrasse (beide Bj. 1910) zur Erzeugung von Halbzeug im wesentlichen für die eigenen Fertigstrassen.

Die kontinuierlichen Drahtstrassen 2 (Bj. 1930) und 3 (Bj. 1955) und zwei Feineisenstrassen (die 280er und 420er Strassen beide Bj. 1924).

Die 1913 erbaute Drahtstrasse 1 war schon 1963 stillgelegt worden. Mit der Schließung der Flüssigphase der NH wurden 1966 auch die Block- und Knüppelstrasse stillgelegt und das Halbzeug wurde fortan aus dem Thyssenverbund bezogen.

Die Drahtstrasse 2 wurde 1966 stillgesetzt und 1968 durch die neue Drahtstrasse 4 die im Bereich des ehem. Knüppellagers errichtet worden war ersetzt.

1971 fusionierte Thyssen die 1968 übernommene Hüttenwerk Oberhausen AG und die Niederrheinische Hütte zur Thyssen Niederrhein AG. Die Draht- und Feineisenstrassen beider Werke arbeiteten nun im Verbund.

Nach der Stilllegung der Drahtstrasse 3 im Mai 1978 arbeiteten in Hochfeld nur noch die neue Strasse 4 und die beiden Feineisenstrassen.

Die Produktion von Feineisen in Hochfeld wurde 1989 beendet, die Mittelstaffel der 280er Strasse befindet sich heute in der Ausstellung des LWL-Industriemuseums Henrichshütte in Hattingen.

Die Drahtstrasse 4 wurde 1997 an die ISPAT Gruppe verkauft und firmierte seit 2007 unter dem Namen ArcelorMittal Hochfeld GmbH.

2013 wurde die Produktion am Standort der Niederrheinischen Hütte eingestellt und die Walzdrahtfertigung zur neuen einadrigen Strasse nach Ruhrort verlagert.

Vielen Dank an das thyssenkrupp Konzernarchiv und das Stadtarchiv Duisburg für die Unterstützung bei der Erstellung dieser Karte.

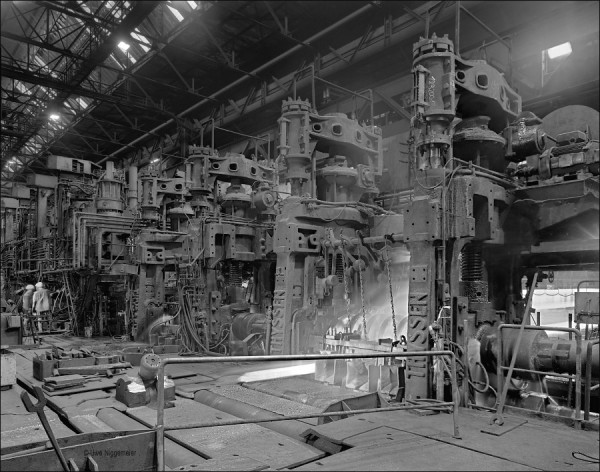

The Last One

in Germany. VDM-Metals’ heavy blooming-slabbing mill NO.2 in Duisburg.

The rolling mill was built by the DEMAG company from Duisburg and was put into operation at the August-Thyssen Hütte in Duisburg on 1 April 1957.

It supplied slabs to Thyssen’s new wide hot strip mill.

Blooms with a weight of up to 27t are supplied by 18 soaking pits and two cranes.

Two DC engines of 4200 kW each run the two.high rolling stand.

They are fed via a hugh Ilgner transformer consisting of two asynchronous motors with 3500 kW four control generators (two each for a rolling motor) and a flywheel with 566 tm².  The rolling mill is owned by VDM-Metals now to produce highly alloyed slabs. After the closure of Reiner Brach’s old Klöckner rolling mill in Bremen it is the last of it’s kind in Germany.

The rolling mill is owned by VDM-Metals now to produce highly alloyed slabs. After the closure of Reiner Brach’s old Klöckner rolling mill in Bremen it is the last of it’s kind in Germany.

Further images.

The 5,1 Meter Heavy Plate Mill

in Mülheim was installed nearly 50 years ago in 1969. The 270 t rolling stand was manufactured by the Sack Maschinenfabrik in Düsseldorf, it was the largest of it’s kind in Germany. Today it is owned by Salzgitter Mannesmann Grobblech and mostly delivers heavy plates to the Europipe tube welding facilities in Mülheim.

Karte der Ruhrgebietsindustrie

Anfang der 1950er-Jahre war das Ruhrgebiet noch jenes einzigartige Labyrinth aus Werksanlagen der Schwerindustrie, Eisenbahntrassen, Kanälen und zersiedelten Großstädten, das der amerikanische Journalist Max Ascoli 1949 unter der Überschrift “Industrial Jungle: the Ruhr” beschrieben hatte. Die kürzlich vom Regionalverband Ruhr veröffentlichten historischen Luftbilder des Ruhrgebiets erlauben nun einen faszinierenden Rückblick auf diese Landschaft.

Als Ergänzung zu den Luftbildern aus dem Jahr 1952 ist diese Karte entstanden.

Sie zeigt die wichtigsten Industriebetriebe der Region in dieser Zeit gegliedert nach Branchen.

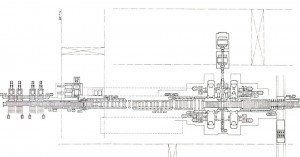

Casting-Rolling Mill

The unique casting rolling unit at ThyssenKrupp’s integrated steel mill in Duisburg, Germany produces strip up to 1,6 m wide with a combined caster and a 7-stand finishing mill in one heat.

The facilities were installed in 1999.

Images now at Stahlseite.

ThyssenKrupp’s Work Horse

the hot strip mill No.2 in Duisburg-Beekerwerth celebrated it’s 50th anniversary in late June.

Installed in 1964 and producing about 6 Mio. tons of hot strip each year it still is one of the most powerfull rolling mills worldwide.

Images now at Stahlseite.

TKS Heavy Plate Mill, Duisburg

The heavy plate mill in Duisburg-Hüttenheim, Germany was built by the Mannesmann company in 1963 to supply plates to their adjecent large diameter pipe welding mill (closed in 1978).

In 1970 the August Thyssen Hütte AG took over the flat rolling business from Mannesmann.

In 1978 the Sack company installed the 3,9 meter four-high rolling stand still in use today.

Images now at Stahlseite.

Coking Plant Schwelgern

The new coking plant Schwelgern in Duisburg, Germany was commmissioned by ThyssenKrupp in 2003 replacing the old August-Thyssen coke ovens.

Two batteries of 70 ovens each were built.

Some images now at Stahlseite.

The Last German Rail

was rolled yesterday at the TSTG rail mill in Duisburg.

The rolling mill exists since 1894 built by the August Thyssen Hütte and sold to the Austrian Voest Alpine group in 2001.

Voest is still producing rails at it’s Donawitz works in Austria.

TSTG’s finishing stands were built in 1924 named “Fertigstrasse 1” back then.

Some images.