The iron foundry Eisenwerk Hasenclever was built on ground of the old Auhammer forge in Battenberg, Germany in 1913. Cast iron crankshafts become the main product.

In 2011 the old cupola furnace was replaced by 6 induction furnaces to produce high temperature resistant steel castings.

More images at Stahlseite.

Tag Archives: Germany

Big Cupola III

Though not as large as the Fritz Winter furnaces this hot blast cupola still churns out more than 30 tons of cast iron each hour.

Heinrich Meier Eisengiesserei in Rahden, Germany was built in 1960.

In 1987 the new cupola furnace was installed by the Küttner company from Essen.

Main products are manhole covers and drainage systems.

Further viewing.

Another Survivor

ESW Röhrenwerke in Eschweiler close to Aachen, Germany is the last survivor of the once huge Eschweiler Bergwerksverein (EBV) combine of coal mines and steel plants and it runs the only planetary tube rolling mill in Europe.

Further images.

The tube mill was founded in 1914 by the Eschweiler- Ratinger Maschinenbauaktiengesellschaft (ERMAG). In 1917 an open hearth shop was added to ensure the steel supply. In 1924 the plant was taken over by the Eschweiler Bergwerksverein (EBV), a mining company mostly owned by ARBED from Luxemburg. Pig iron was now supplied by the nearby EBV blast furnaces (Concordiahütte). In 1957 a new electric arc melt shop was built on ground of the now dismantled blast furnace site. In 1964 a continuous caster was added.

An new innovative planetary tube rolling mill (PSW) gradually replaced the outdated pilger rolling mills in 1976.

In 1984 the site was sold to the Maxhütte steel company from Bavaria. The EAF melt shop closed in 1986 and one year later the Maxhütte went bancrupt. In order to save the new tube rolling mill the former plant manager, among others, took the mill over in 1987.ESW Röhrenwerke produces seamless steel tubes for the oil and gas industry, boilers and engineering.

Zeitzer Guss

The iron foundry Zeitzer Guss runs one of the largest induction furnaces in Germany. Founded in 2007 it is the latest foundry in Germany. It was built on ground of the much older ZEMAG (Zeitzer Eisengießerei und Maschinenbau AG) plant from 1855. Zeitzer Guss produces hand formed castings up to 30 tons a piece.

Further images at Stahlseite.

Big Cupola II

The Fritz Winter iron foundry in Stadtallendorf, Germany operates one of the largest foundry melt shops worldwide. Two hot blast cupola furnaces and ten induction furnaces can melt up to 2800 tons of iron each day.

The company was founded in 1951 on ground of a former explosives factory.

Today the plant is the largest independent foundry in Europe employing 3500 people.

Main product are engine blocks and brake discs for the car industry.

Further images at Stahlseite.

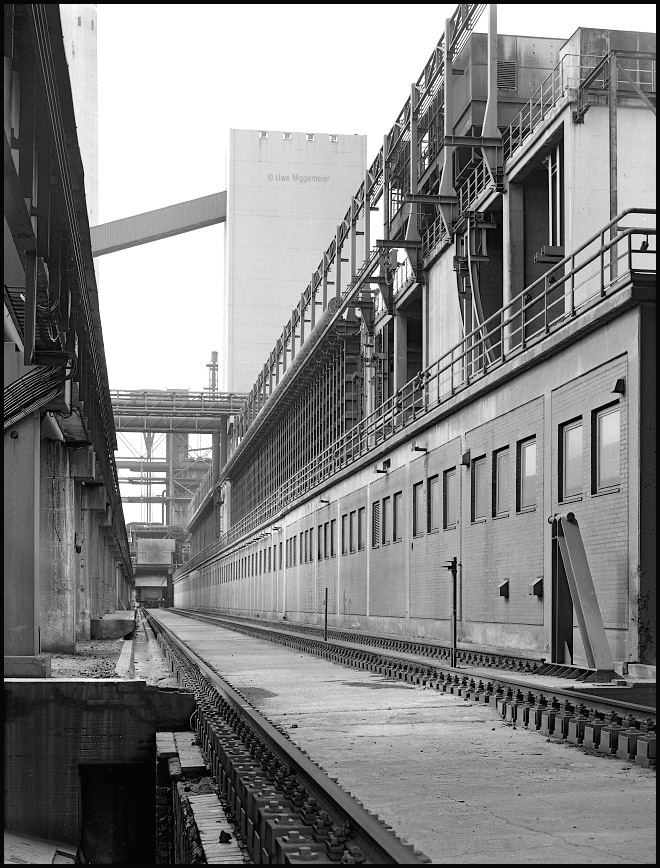

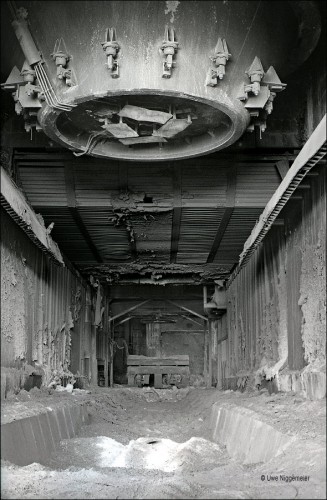

Kokerei Kaiserstuhl

These days the last remains (coking coal tower, dry quenching facilities) of the coking plant Kaiserstuhl in Dortmund, Germany are knocked down.

The plant was built in 1992 to be the most modern coke making facility in Europe.

It supplied coke to the nearby Hoesch blast furnaces. The plant inluded two coke oven batteries of 60 furnaces each, and both a dry and a wet quenching facility.

When ThyssenKrupp announced the closure of it’s (former Hoesch) blast furnaces Kaiserstuhl was shut down after being in operation for just eigth years .

Ten years ago most of the mill was dismantled and rebuilt in the Shandong province, China.

This relocation was documented in the exiting movie Losers And Winners.

Further images of this plant at Stahlseite.

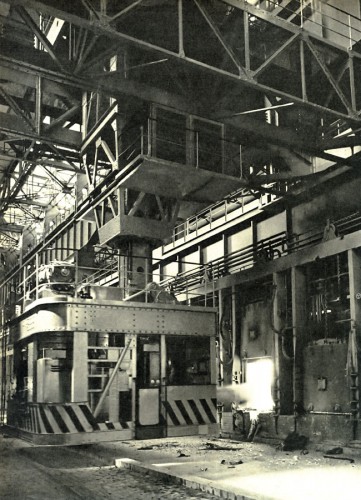

Last Open Hearth Built In West Germany ?

In between 1954 and 1962 the Hoesch company in Dortmund, Germany built it’s third open hearth melt shop (SM-Stahlwerk III).

Two 180 ton furnaces were installed by 1956, two DEMAG 210 ton furnaces were added in 1961 and 1962. These might have been the last to be commissioned in West Germany.

Monthly output was less than 100000 tons, not enough to compete with the new BOF shop in Dortmund Hörde built in 1963 producing more than 300000 t/m.

The open hearth shop 3 was closed in 1982.

Some images of it’s remains: Stahlseite.

The Last Furnace In Town

My hometown Hagen once was one of the major steel producing communities in Germany.

Blast furnaces,open hearth shops and numerous foundries shaped the confined townscape in the narrow valleys of the Volme and Ennepe rivers.

The largest steel mill, the Hasper Hütte owned by the Klöckner company, was closed in 1972 and the huge Wittmann steel foundry next to it just one year later.

The last major steel producer in town, the open hearth shop of Stahlwerke Südwestfalen was shut down in 1976, smaller ones like the Remy speciality steel mill followed in the 1990ies.

The Eisenwerk Geweke was founded in 1910 and is specialized in steel fittings.

A five ton electric arc furnace and a small induction furnace are producing castings up to four tons a piece.

Further viewing at Stahlseite.

It helps to know…

Big Cupola

Eisenwerk Brühl south of Cologne, Germany runs one of the largest cupola furnaces in Europe.

Installed in 1981 it delivers 90 tons of hot metal each hour.

Up to 26000 engine blocks can be casted daily.

The foundry was established in 1927 by Georg and Maria Sandmann.

Right from the start the main products were cast iron engine blocks for the car industry.

It is said that one out of five blocks in the world comes from Brühl.

Further images.